Wide material compatibility: Screw Dosers are suitable for virgin, regrind materials, and masterbatch

2026/02/07 By le zhan

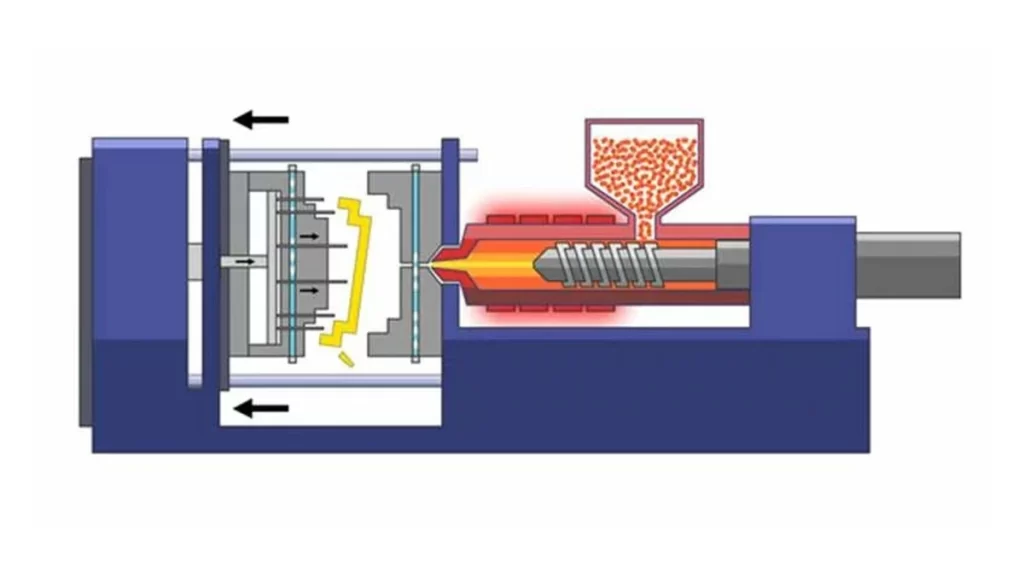

For modern processors requiring precise and repeatable metering of various raw materials, Screw dosers offer a practical solution. Whether the production line is conveying virgin granules, screened regrind, masterbatch, or functional additives, a well-configured screw feeder can achieve proportional mixing with minimal operator intervention. Simply put, the device transforms the variability of the raw material flow into a stable input required by injection molding machines or extrusion lines. This guide will explain why Topstar’s screw dosers are widely compatible with different polymer compounds, how microcomputer control and dual operating modes provide accuracy and flexibility, and which operating practices maximize performance.

The Versatility of Screw Dosers

The superior performance of screw dosers stems from the inherent adaptability of their physical metering mechanism. The core component of the device is the metering screw, which conveys material at a rate proportional to its rotational speed and the volumetric displacement per revolution. Unlike gravity feeders or paddle systems that rely on the overall flow characteristics of the material, the positive displacement nature of screw dosers makes them less sensitive to particle shape, bulk density, or flowability. Therefore, as long as the screw geometry and drive settings are matched to the material type, a screw doser can meter virgin polymer granules, recycled flakes, and masterbatch powders or granules using the same hardware platform.

However, not all materials behave the same. Filled compounds and fiber-reinforced resins may be more abrasive and have greater variations in bulk density, while fluffy masterbatches and powdered additives may require controlled agitation to prevent bridging. To address these situations, the Topstar screw doser is equipped with configurable feed chambers, interchangeable screws, and agitators within the hopper. These enhancements ensure stable material flow into the metering screw and prevent pulsation at the injection molding machine.

Precise Automatic Proportional Metering and Microcomputer Control of Screw Dosers

Screw dosers equipped with microcomputer controllers achieve automatic proportional metering by continuously adjusting the screw speed to maintain the target additive ratio, even when the main material flow changes. The controller receives input data—target percentage, measured feed rate, and sometimes feedback from a gravimetric blender or in-line scale—and calculates the appropriate setpoint for the metering screw. This tight closed-loop control method eliminates operator guesswork, reduces color drift, and maintains consistency in the mechanical and aesthetic properties of molded parts.

First, it supports recipe storage and recall, allowing for instant loading of color and additive ratios for specific parts or customers. Secondly, the controller enables gradual acceleration and deceleration, preventing under- or over-feeding of the hopper, thus protecting the injection molding machine and downstream quality control systems.

Another advantage is automatic compensation. When the injection molding machine temporarily slows down, the controller senses the reduced demand for the primary material and proportionally reduces the screw feeding speed to maintain a constant mixing ratio. This proportional control can be achieved through volumetric or gravimetric control, with the latter offering higher accuracy. Regardless of the mode, the microcomputer-controlled screw metering device translates process fluctuations into stable, predictable ratios, helping manufacturers improve first-pass yield.

Two Operating Modes: Injection Molding and Extrusion

The screw doser is carefully designed to serve both injection molding and extrusion processes, offering two operating modes to match the metering behavior to the target process. In injection molding applications, metering typically responds to the demand of each injection or cycle, requiring precise timing to coincide with the plasticizing phase for short bursts of material. In contrast, extrusion requires continuous and stable material delivery at a preset kg/h rate. The efficient screw metering device meets the needs of both applications through flexible control logic and mechanical design.

For injection molding machines, the controller typically integrates with the machine’s cycle signal, utilizing proportional pulses or machine status inputs to coordinate metering intervals. The screw metering device then meters colorants or regrind in sync with the injection molding machine’s output, preventing hopper shortages or material surges, thus preventing variations in injection weight. For extruders, it operates in continuous mode, maintaining a constant screw speed and delivering the required weight percentage over long production runs. The device’s screw geometry and feed port design ensure uninterrupted feeding, avoiding pulsations that could lead to variations in the quality of the extrudate.

Processing Virgin Materials, Recycled Materials, and Masterbatches

The practical advantages of Topstar screw dosers are evident when mixing materials with different characteristics, such as virgin polymer granules, recycled flakes, and concentrated masterbatches. Each material requires a tailored processing method to ensure dosing accuracy and product quality. Virgin granules typically have good flow properties, resulting in stable and repeatable dosing. Recycled flakes often have uneven bulk density and irregular shapes; these characteristics require robust agitation and anti-bridging hopper designs to ensure smooth material flow into the screw. Masterbatches, especially high-concentration colorants, may be dense and abrasive, or fluffy and electrostatic; reliable dosing depends on the appropriate screw pitch and controllable feeding energy.

Integration with Injection Molding Machines and Other Auxiliary Equipment

The successful implementation of screw dosers depends not only on the metering unit itself but also on system integration. Integration points include machine status signals, gravimetric feedback loops, network communication, and safety interlocks. When the screw-type metering device communicates with the injection molding machine, it can anticipate production demands and adjust the metering speed in advance, reducing transient errors and making mixing smoother during cycle transitions. For applications requiring higher precision, connecting it to a gravimetric blender creates a closed-loop control system that corrects deviations in real time. This method measures the actual output mixture and automatically adjusts the screw speed to restore the target ratio.

Providing Broad Material Compatibility

Broad material compatibility is a significant advantage of modern screw dosers and a key reason why they are indispensable in today’s injection molding processes. Screw dosers can accurately and proportionally meter virgin materials, recycled materials, masterbatches, and additives, transforming various raw materials into a stable and controllable feedstock for the injection molding machine. With microcomputer control and dual injection/extrusion modes, they achieve consistent mixing ratios, reduce material waste, and improve product repeatability.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2026/02/07

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2026/02/07

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2026/02/07

- What factors can cause delays in the injection molding process of plastic molding machine? 2026/02/07

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar