170 ton vs 260 ton injection molding machine: Product Capacity & Application Scope

2025/12/22 By le zhan

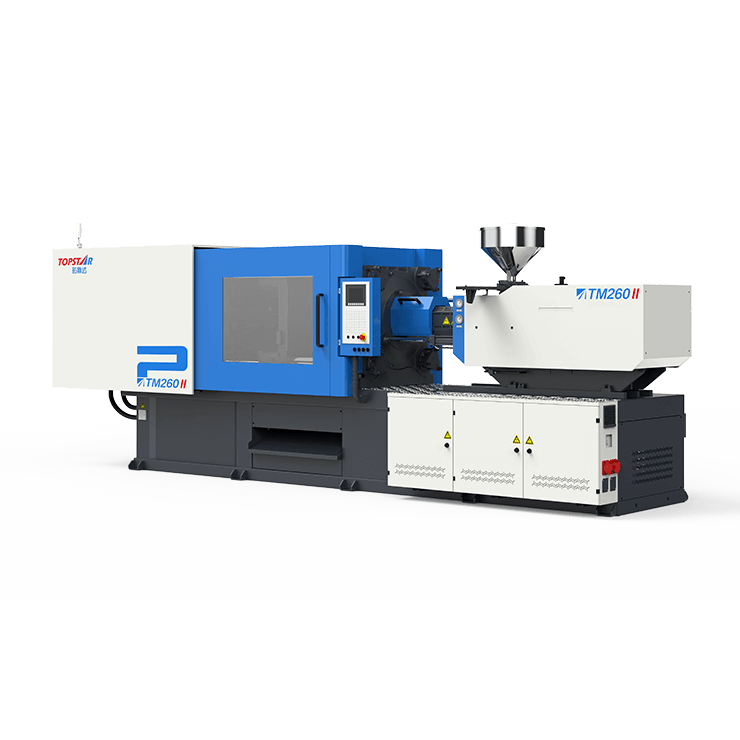

For medium-sized plastic product manufacturers, the choice between a 170 ton and a 260 ton machine typically depends on product size and material requirements, which directly impact part quality, production efficiency, and procurement budget. Therefore, we have compared the production capacity, application range, mold requirements, and material compatibility of the 170 ton and 260 ton injection molding machine from a practical perspective to help you choose the machine that best suits your product and production goals.

Comparison of the 170 ton and 260 ton Injection Molding Machine

The main differences between a 260 ton and a 170 ton injection molding machine lie in clamping force, maximum injection volume, mold size, and structural rigidity. These differences directly affect the types of parts you can produce, the achievable production cycle times, and the machine’s suitability for thick-walled parts or parts with high internal stress.

Key Differences:

Clamping Force: The 260 ton injection molding machine offers a higher clamping force, allowing you to mold larger parts, parts with larger projected areas, or use higher injection pressures without flashing. This is crucial for molding parts with numerous thin-walled features or parts requiring high holding pressure to avoid sink marks and voids.

Injection Volume: Machines with higher clamping force typically have larger injection units, resulting in higher injection volumes. This makes 260 ton injection molding machines more suitable for single-shot molding of large parts or multi-cavity molds.

Mold Size and Tie Bar Spacing: The platen area and tie bar spacing of the 260 ton injection molding machine can accommodate wider and taller mold assemblies. If your parts require large inserts, multi-cavity molds, or complex side actions, a larger machine can often simplify mold design.

In contrast, the 170 ton injection molding machine is generally more suitable for small mechanical parts, compact housings, consumer electronics components, and scenarios where footprint, faster cycle times, and lower initial investment costs are critical.

Clamping Force, Injection Volume, and Production Capacity of the 260 ton Injection Molding Machine

When we discuss production capacity, we consider how many parts a machine can produce per hour and the size of the parts. The 260 ton injection molding machine offers higher clamping force, enabling higher injection pressures and providing better control when producing thicker parts or parts with larger projected areas. Therefore, this directly affects the integrity and repeatability of the parts.

Factors to consider when choosing:

Clamping force: The required clamping force is proportional to the projected area of the part and the cavity pressure. Larger projected areas require greater clamping force to prevent flashing. If the projected area of your part approaches or exceeds the maximum safe projected area of a 170 ton injection molding machine at your set safety margin, a 260 ton injection molding machine should be chosen.

Injection volume: Larger injection units provide greater injection volume, allowing for the molding of larger parts in a single shot. For example, applications such as automotive interior panels, heavy-duty housings, or large medical equipment enclosures often require the larger injection volume offered by a 260 ton injection molding machine platform.

Cycle time impact: While larger machines may have slightly longer mechanical response times, modern servo-driven 260 ton injection molding machines can maintain efficient cycle times through optimized injection curves and powerful clamping force. When properly matched, a 260 ton injection molding machine can improve net productivity.

Common Application Areas

260 ton injection molding machines are suitable for a wide range of industries and part types, with applications far exceeding the practical capabilities of a 170 ton machine.

Common application areas for 260 ton injection molding machines:

Automotive: Large interior panels, door trims, center consoles, or engine compartment structural components requiring large molds and higher holding pressure.

Appliance housings: Rice cooker housings, dishwasher housings (internal components), and large control panel bezels.

Medical device components: Large instrument housings or sterilizable trays requiring thicker walls and precise holding pressure.

Consumer goods: High-end, large toy components or large cosmetic packaging where appearance and rigidity are critical.

In contrast, 170-ton injection molding machines are typically suitable for:

Small to medium-sized electronic product housings

Small consumer goods and accessories

Thin-walled beverage bottle caps or small components where high cavity counts on smaller molds provide optimal economic benefits.

Differences in Material Compatibility

Material compatibility is also very important in the selection of an injection molding machine. 260 ton injection moulding machines offer greater material compatibility and a broader processing window, making them especially suitable for processing high-performance polymers. The Importance of Material Selection:

For example, engineering plastics (such as PA66 GF and PBT GF) have good thermal expansion resistance but require higher injection pressure to fill complex moulds. A 260-ton injection molding machine’s greater clamping force and larger screw diameter can meet these requirements. Materials such as PEEK, LCP, or high-viscosity blends require a robust injection unit and a stable barrel heating system. 260 ton injection molding machines typically offer injection stroke and screw options necessary for these materials. Additionally, thin-walled parts often require fast injection and high fluidity. In contrast, thick-walled structural parts benefit from the larger screw capacity and higher clamping stability of a 260-ton injection molding machine.

In terms of processing window and machine flexibility, a larger injection volume allows you to use various screw diameters and length-to-diameter ratios, thereby optimizing production of shear-sensitive materials. Furthermore, servo-driven 260 ton injection molding machines typically offer more precise metering control, reducing shear heating of sensitive elastomers or filled composite materials.

Molds, Mold Size, and Part Complexity

Molds are the primary recurring cost in injection molding. A 260 ton injection molding machine can accommodate larger molds and more complex mold structures, but this also brings several considerations regarding molds and operation.

First, in terms of mold compatibility, a larger platen area can accommodate larger molds, multi-layer inserts, and slider/side mechanisms. This flexibility enables the production of complex parts, such as side cores, thread demolding, and mechanical demolding, that smaller injection moulding machines cannot effectively support. At the same time, larger molds are heavier and require appropriate lifting equipment, mold bases, and maintenance space. When installing a 260 ton injection molding machine, mold handling equipment, crane capacity, and floor load capacity should be considered.

While a 260 ton injection molding machine can achieve high-cavity production of large parts or complex combination molds with multiple part geometries, this can significantly reduce the cost per part but increases mold complexity and initial investment. Therefore, we recommend coordinating mold design and selecting the injection molding machine at an early stage of the project. If you plan to run multi-cavity molds on a 260 ton injection molding machine, simulate the mold weight, cooling requirements, and installation/removal processes in your factory layout planning to avoid unexpected issues later on.

Please make your choice based on your specific production needs.

The choice between a 170 ton and a 260 ton injection molding machine depends more on product geometry, material selection, molding strategy, and business growth plans. The 260 ton machine offers greater injection volume, higher clamping force, and the ability to run larger molds or more cavities – advantages that facilitate the production of larger structural components and engineering plastic products, and that enable expansion into more complex product lines. Conversely, the 170 ton machine is generally more advantageous in terms of capital efficiency, footprint, and quick mold changes for small parts and diversified product portfolios.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/12/22

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/12/22

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/12/22

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/12/22

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar