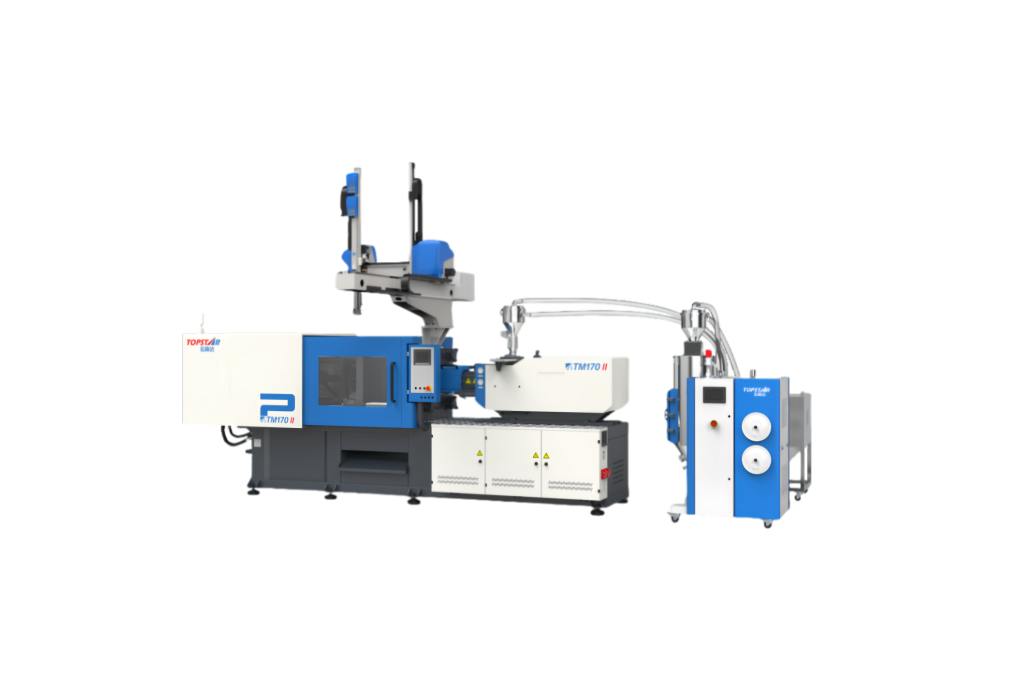

170ton injection molding machine: Water cup injection molding production

2025/10/22 By le zhan

The global plastic water cup market produces over 50 billion units annually. For these manufacturers, every second of cycle time translates into real profit. Even a two-second reduction in production per cup can save hundreds of millions of dollars for a 24/7 factory. However, many water cup manufacturers report inefficiencies in their factories, such as cycle times exceeding 40 seconds, PP material sticking to machine screws, inconsistent weight, and slow demolding, which result in 5-8% of cups being damaged. As a professional injection molding machine equipment manufacturer, Topstar will share a case study specifically for water cup injection molding. In this solution, we will use a 170 ton injection molding machine as the core equipment for water cup production. Let’s explore how it achieves this.

Why is a 170 ton injection molding machine suitable for PP water cup production?

Not all injection molding machines are suitable for water cup production. The 170 ton injection molding machine was chosen because it offers an ideal balance of clamping force and precision, making it particularly well-suited for PP cup production. The importance of this clamping force is evident in the fact that PP cups require sufficient clamping force to maintain mold closure during the injection process. A standard 39g two-cavity mold for a water cup requires a clamping force of 150-180 tons, and a 170 ton clamping force hits this optimal value. Using a machine with a lower clamping force risks flashing, while a larger machine would consume excessive energy.

In terms of injection volume compatibility, the injection volume of a 170 ton injection molding machine (typically 250-393 cubic centimeters) matches the total material volume required for two 39g PP cups. This prevents machine overload or incomplete “short shots.” Furthermore, the mold platen dimensions of the Topstar TMll170t injection molding machine accommodate standard two-cavity water cup molds, eliminating the need for custom mold modifications.

Electroplated Screw and Discharge Temperature Control for the 170 ton Injection Molding Machine

When using PP material for water cup injection molding, it tends to adhere to uncoated screws and requires precise temperature control to prevent degradation. The Topstar TMll 170 ton injection molding machine solves these two problems with two key features:

Electroplated Screw: Unlike the uncoated steel screws found in most injection molding machines, Topstar’s electroplated screw effectively prevents PP from sticking. This means no material buildup, faster plasticization, and reduced scrap.

Discharge Temperature Control: The discharge port in this injection molding machine utilizes a dual-sensor system, maintaining a temperature accuracy of ±1°C. This ensures a stable PP flow rate and a uniform cup wall thickness.

Proportional Back Pressure Control for Precise Plasticization

The pre-plasticization stage is a pain point for many injection molding machines, as fixed back pressure settings can lead to air bubbles in the water cup or inconsistent part weight. Topstar’s 170 ton injection molding machine addresses this issue with proportional back pressure control.

First, in a multi-level setting, the operator can adjust three to five back pressure levels using the 170 ton injection molding machine’s touchscreen. This removes air from the PP melt and ensures uniform density. Unlike manual back pressure adjustment, the proportional system updates in real time, eliminating the need for machine downtime. Many customers producing water cups have reported that their cup weight deviation has been reduced from ±1.2 grams to ±0.5 grams, better meeting retail packaging standards. One production manager commented, “We used to sort 8% of our cups due to weight issues. With the TMll 170t backpressure control, that number has been reduced to less than 1%, saving us 20 hours of sorting time per week.”

20% Increase in Ejector Force, Fast and Damage-Free Demolding

Demolding is a bottleneck for 40% of water cup production lines. Weak ejector force can lead to cups sticking to the mold, which may require manual intervention or cause scratches or deformation. Topstar’s 170 ton injection molding machine boasts 20% higher ejector force than previous-generation or competitor 170-ton machines. Its 8mm diameter ejector pin and dual-cylinder ejection system enable easy ejection of cups from the mold, eliminating sticking and the need for manual intervention. Furthermore, the greater and evenly distributed force prevents cups from bending or scratching. Furthermore, the one-touch automatic, precise mold adjustment setting accommodates taller cups or cups with handles, enabling customers to expand their product lines using these machines without purchasing a new injection molding machine.

Water Cup Production Case Study

Let’s use a case study to illustrate the value of a 170-ton injection molding machine in the production of water cups.

Machine used: Topstar TMll 170 ton injection molding machine.

Product specifications: 39g PP water cup (84mm height, 45mm diameter), double-cavity mold.

The 170-ton injection molding machine achieves the following results:

Cycle time: 32 seconds (18% speed increase).

Scrap rate: 2.3% (67% reduction).

The electroplated screw eliminates material buildup, proportional back pressure ensures consistent weight, and high ejection force reduces demolding time, achieving efficient and high-quality production.

The TMll 170t is the ideal machine for water cup production

For manufacturers looking to optimize their water cup injection molding production, a 170 ton injection molding machine offers an ideal balance of size, power, and efficiency. The Topstar TMll 170t injection molding machine goes even further. Its coated screw, proportional backpressure control, and 20% higher ejection force address the key challenges of other machines. In practical applications, it has achieved a cycle time of 32 seconds and a 23% increase in output.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/10/22

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/10/22

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/10/22

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/10/22

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- cabinet dryer

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- injection moulding dryer

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar