6 major advantages of Topstar granulator machine in processing rigid plastics and brittle plastics

2026/01/14 By le zhan

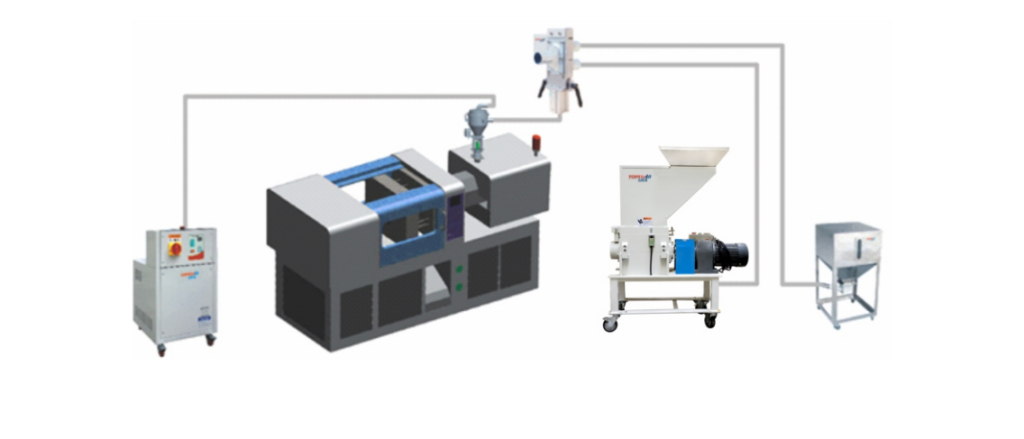

When customers talk about “difficult-to-process” plastics in injection molding, they refer to materials that tend to break, generate fine powder, and overheat during grinding—problems that lead to contamination and quality issues. The Topstar granulator machine is designed to address these pain points. With screenless grinding technology, low-speed gear-driven cutters, a rapid recycling process, and heavy-duty cutter options, Topstar solves the practical problems customers face when recycling PC, nylon, ABS, and other brittle resins in injection molding, reducing waste and improving recyclability.

Screenless Granulator Machine Design

A major innovation of the Topstar granulator machine is its screenless design. Traditional granulators rely on perforated screens to size the material as it leaves the cutting chamber. While screens work effectively for many thermoplastics, they create two persistent problems when processing rigid and brittle plastics: first, long fibers or irregularly shaped fragments easily clog the screens; and second, forcing fragments through narrow apertures generates excessive fine powder.

Topstar’s screenless granulator machine avoids these drawbacks through controlled cutting geometry and a segmented crushing process. Instead of forcing material through small holes, the machine grinds it to produce uniformly sized flakes and chips without abrasive action, thus avoiding dust generation. This directly results in three benefits:

- Reduced downtime: Operators spend less time cleaning and replacing clogged screens, increasing machine availability.

- Cleaner workplace: Reduced airborne fine particles, lower cleaning requirements, and reduced worker exposure risks.

- Higher quality regrind – With no fine powder contaminating the material, the regrind can be mixed with virgin resin more predictably.

From an operational perspective, the screenless granulation method reduces the number of consumables and simplifies maintenance. Screenless granulation is particularly advantageous for customers processing waste materials such as PC, nylon, and ABS; this design tolerates uneven feed and minimizes clogging.

Uniform granulation, minimal powder residue, and reusability

When manufacturers reintroduce recycled materials into the production process, uniform particle size is crucial. Particle size variations and excessive fines can alter melt flow characteristics, leading to air entrapment or unacceptable colour and surface defects in finished parts. Topstar’s granulator machines focus on producing granules with a uniform particle size distribution and minimal powder generation, thereby enabling more precise control over mixing ratios and melt behavior.

So how does Topstar achieve uniform granulation and minimize powder generation?

The machine optimizes its rotor and cutting geometry for brittle fracture rather than abrasive grinding. This controlled fracture mechanism causes the material to break along natural fracture planes, producing flakes of similar size rather than dust. Furthermore, low-speed, high-torque operation reduces frictional heat and remelting at the cutting edges. As a result, you’ll see easier downstream processing and metering, with smoother particle flow in the hopper and less bridging. Reduced fines and melt smearing improve the color and surface consistency of remelted products, enabling customers to set specific regrind ratios without excessive trial-and-error.

Granulator machine with a 30-second rapid recycling system

If you want to recycle brittle waste without compromising color or polymer quality, speed is crucial. Topstar granulator machines’ rapid recycling system is designed to produce ready-to-use regrind in approximately 30 seconds of continuous processing time, for a variety of batch sizes – an advantage that reduces the time the waste is exposed to air, moisture, and high temperatures.

Why is this important?

Exposure time affects oxidation, moisture absorption, and even short-term thermal degradation. For some resins, especially transparent or light-colored resins, prolonged exposure to air during grinding can lead to surface oxidation or slight discoloration. Similarly, moisture absorption on the particle surface increases the risk of hydrolytic degradation of the regrind during subsequent melt processing. The Topstar plastic granulator machine reduces the recycling cycle to tens of seconds, thus minimizing these risks.

Specific advantages include: reduced incidence of color deviations in remelted parts, reduced need for subsequent drying, and the ability to instantly recycle scrap during production downtime. For applications requiring high color fidelity—such as automotive trim parts (PC/ABS blends) or consumer electronics housings—this rapid turnaround helps you meet aesthetic specifications while reducing scrap inventory.

20-28 RPM Low-Speed Operation and Teeth Cutters Design Granulator machine

In hard-plastic processing, cutting speed is a critical factor affecting performance. Topstar’s plastic granulator machines use a specially designed low-speed rotor (20-28 RPM) and a high-torque gear-driven cutter assembly. This combination is optimized for brittle fracture and offers several advantages:

- Reduced Heat Generation: Low speed minimizes frictional heat generation, preventing edge softening or sticking and reducing fines while maintaining polymer integrity.

- Cleaner Cutting: The teeth cutters provide stable, repeatable cutting force with minimal vibration, producing uniform chip shapes rather than jagged fragments.

- Lower Noise: The low-speed operation inherently reduces noise compared to high-speed grinding, improving the workshop environment.

- Improved Energy Efficiency: While lower speeds might imply lower throughput, the high-torque gear drive concentrates energy where it’s needed most.

This configuration is particularly suitable for tough, brittle resins such as PC, certain nylon grades, and ABS, where high-speed cutting can produce long fibres, generate heat, or cause remelting, degrading the quality of the recycled material. The teeth cutter design also handles intermittent feeding better, reducing the risk of cutter jamming or motor stalling, making it a reliable solution for processing irregularly shaped scrap and mixed batches.

Shaft Gear-Motor, Lubrication-Free and Space-Saving

Maintenance and footprint optimization are often overlooked practical considerations in equipment selection. The shaft gear-motor drive used in Topstar’s granulator machines addresses both issues simultaneously without requiring external lubrication. Unlike traditional gearboxes that require regular oil changes, seals, and separate gearbox space, the hollow shaft assembly offers several operational advantages:

- No External Lubrication Required: Eliminates the need for routine oil changes and reduces the risk of contamination from leaks—especially important in clean production areas. Space-Saving: The compact, integrated design reduces the machine’s footprint, allowing for closer integration with molding units or presses and simplifying factory layout.

- Reduced Maintenance Burden: Fewer maintenance points mean your team spends less time on routine maintenance, freeing up more time for value-added activities.

- Cleaner Environment: The absence of oil mist or drips simplifies cleaning and reduces the risk of product contamination in nearby operations.

Optional SKD-11 Tool Steel – Suitable for Abrasive and High-Strength Applications

Tool life directly impacts downtime, maintenance costs, and the consistency of granule output. Topstar offers optional SKD-11 tool steel for blades and wear parts – a significant advantage for abrasive or high-load applications.

Advantages of SKD-11 tooling include:

- Extended Blade Life: Blades and holders wear more slowly, maintaining cutting quality and reducing variations in regrinding over extended use.

- Reduced Replacement Frequency: Fewer blade replacements reduce parts expenditure and labor costs.

- Higher Precision: SKD-11 maintains a sharper profile for longer, ensuring consistent granule geometry and reducing fines generated by tool wear.

- Increased Uptime: Longer maintenance intervals mean more efficient production time and less downtime.

Achieve Easy Operation and Excellent Crushing Results

The advantages of Topstar granulator machines lie in their screenless design, uniform granulation, rapid recycling cycle, low-speed, high-torque blades, shaft gear-motor, and durable SKD-11 tooling – combined, these provide a powerful, efficient, and low-cost-per-piece recycling solution for rigid and brittle plastics. This results in easier operation and excellent crushing performance.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2026/01/14

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2026/01/14

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2026/01/14

- What factors can cause delays in the injection molding process of plastic molding machine? 2026/01/14

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- cabinet dryer

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar