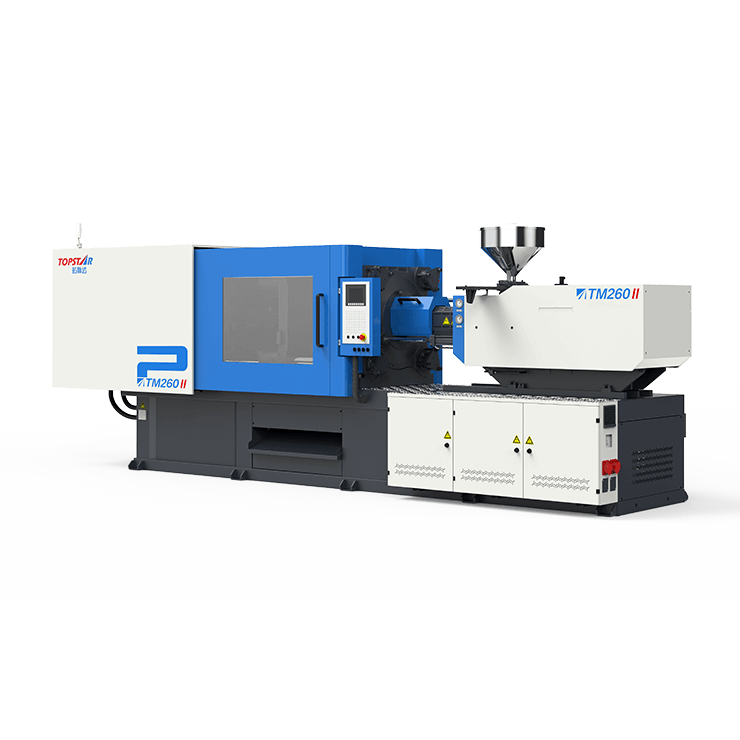

Case Study: Injection Molding of Rice Cooker Shell Using a 260-Ton Injection Molding Machine

2025/11/03 By le zhan

Unstable plasticization, inaccurate demolding, and excessively long production cycles lead to significant losses in production efficiency. On average, each factory loses tens of thousands of dollars annually due to PP material waste and failure to meet production targets. As product managers at Topstar, we’ve heard many clients raise these issues. One large home appliance brand approached us seeking solutions for rice cooker shell production, as they needed an injection molding machine capable of handling the unique flowability of PP material, maintaining a 30-second production cycle, and seamlessly integrating with their automated systems. We provided them with a 260-ton injection molding machine from the Topstar TMll series. Therefore, we will use this case study to demonstrate how to enhance production, achieve stable quality, reduce production cycles, and minimize waste.

Why equip a rice cooker shell with a 260-ton injection molding machine?

Rice cooker shells are typically 3-4 mm thick and 30-40 cm in diameter. Injection molding has specific requirements: sufficient clamping force to prevent flash, precise plasticization of the PP material, and compatibility with automated systems for mass production. Topstar’s 260-ton injection molding machine fully meets these requirements:

Clamping Force: The 260 ton clamping force is sufficient to maintain a tight seal in the single-cavity mold during the injection molding process. This is crucial for low-viscosity PP materials, as insufficient clamping force can easily lead to flash.

Injection Volume: The injection molding machine‘s injection volume can easily accommodate 180-200 grams of PP material, which is typically used for the outer shell of a rice cooker.

Size Compatibility: The tie rod spacing of the TMll 260 ton injection molding machine is ideal for accommodating large, shallow molds required for rice cooker shells.

Precision PVD alloy screw head, with superior PP plasticizing technology

PP is the preferred material for rice cooker shells due to its heat resistance, durability, and cost-effectiveness. This 260 ton injection molding machine’s precision PVD alloy screw head assembly solves the material adaptability problem. The PVD coating on the screw head reduces friction, allowing PP to melt evenly and flow smoothly into the mold. Unlike standard screw heads, it can handle the low melting point of PP (160–170°C) without degradation.

Simultaneously, the screw’s 22:1 L/D ratio ensures complete melting of PP granules, eliminating unmelted particles and preventing surface defects on the casing. This high precision reduces the brand’s defect rate from 2.1% to 0.3%. Furthermore, by optimizing the plasticizing process, material waste is reduced by 60%. The TM260’s PVD screw head changes this, resulting in a smooth and uniform casing surface that eliminates scrap due to deformation or uneven melting.

Automatic Mold Opening Position Compensation in the 260-ton Injection Molding Machine

In the mass production of rice cooker shells, injection molding robots play a crucial role in demolding. Inaccurate mold opening positions can lead to robot gripping failures, thus extending the production cycle. The automatic mold opening position compensation function of the 260-ton injection molding machine effectively solves this problem. Guided by a unified control system, this function can automatically adjust the mold opening position (with an accuracy of ±0.1mm) based on real-time feedback from the injection molding robot, thereby ensuring perfect alignment between the injection molding robot’s clamp and the shell demolding point.

Consistent mold opening positions eliminate the need for manual adjustment, ensuring timely completion of the 30-second cycle. The injection molding robot now completes demolding in just 2 seconds, without any delay. Furthermore, the compensation function prevents collisions between the robot and the mold, extending mold life by 30% and providing better protection for the mold.

The integrated control system of the 260-ton injection molding machine enables coordinated production

The true advantage of the 260-ton injection molding machine lies in Topstar’s independently developed integrated control system. This system integrates the machine, auxiliary equipment, and automation systems into a unified and coordinated workflow. Through real-time communication, the system synchronizes data between the dryer, injection molding machine, and injection molding robot. For example, if the dryer detects moisture in the PP, it signals the machine to extend the plasticizing time, thus preventing plastic expansion. Additionally, step-by-step optimization is implemented, with each stage of production finely tuned: material pretreatment, plasticization, injection molding, and demolding. The system adjusts these parameters in real time based on production data. Finally, all process parameters are recorded and accessed via touchscreen or the factory ERP system, ensuring traceability of quality control. Customers can use this data to identify bottlenecks and further optimize production processes.

Case Study Results

After using the Topstar TMll series 260 ton injection molding machine for six months, this appliance brand achieved significant results in rice cooker shell production:

Cycle time: Consistently maintained at 30 seconds, with a 16% increase in daily output.

Defect rate: Reduced from 2.1% to 0.3%, saving tens of thousands of dollars in material waste annually.

Automation efficiency: Clamping failure rate reduced from 8% to 0.5%, with a 94% reduction in unplanned downtime.

Mold life: Extended by 30%, saving $15,000 in mold replacement costs.

This customer told me, “We set high goals for the TM260, and it exceeded them. A 30-second molding cycle, consistent quality, and seamless automation make this injection molding machine the core of our rice cooker shell production.”

Key Considerations for Rice Cooker Shell Manufacturing

We hope this case study will provide manufacturers looking to purchase and use a 260-ton injection molding machine, or for rice cooker shell production, with several key considerations:

Prioritize Material-Specific Components: For PP, PVD alloy screw heads are essential as they ensure consistent plasticization and reduce waste.

Invest in Automation Integration: Automated mold opening compensation eliminates manual adjustments and robot malfunctions, keeping production cycles on track.

Choose Integrated Controls: Unifying the injection molding machine, auxiliary equipment, and automation systems reduces bottlenecks and ensures traceability.

Higher Standards in Rice Cooker Shell Production

Topstar The TM260 series 260 ton injection molding machine precisely controls PP plasticization through its precision PVD alloy screw head. Its automatic mold opening compensation function enables seamless integration with injection molding robots, and the integrated control system coordinates every production step. All of this achieves a rapid molding cycle of 30 seconds. For the appliance brand in this case study, the TM260 not only solved their immediate problems but also brought long-term value by reducing waste, increasing output, and extending equipment lifespan.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/11/03

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/11/03

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/11/03

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/11/03

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar