Guide to All-Electric Injection Molding Machine for Precision Plastic Parts: 90T-200T TEII Series

2025/11/28 By le zhan

Precision plastic parts, such as medical components, automotive sensors, or electronic housings, require extremely high consistency. Even a deviation of 0.01 mm can render a part unusable. Hydraulic injection molding machines, due to their fluid-driven motion, struggle with pressure fluctuations, leading to uneven clamping and slow response times, which in turn cause injection instability. All-electric injection molding machine that uses servo motors to perform all functions, eliminating these problems and achieving precise control.

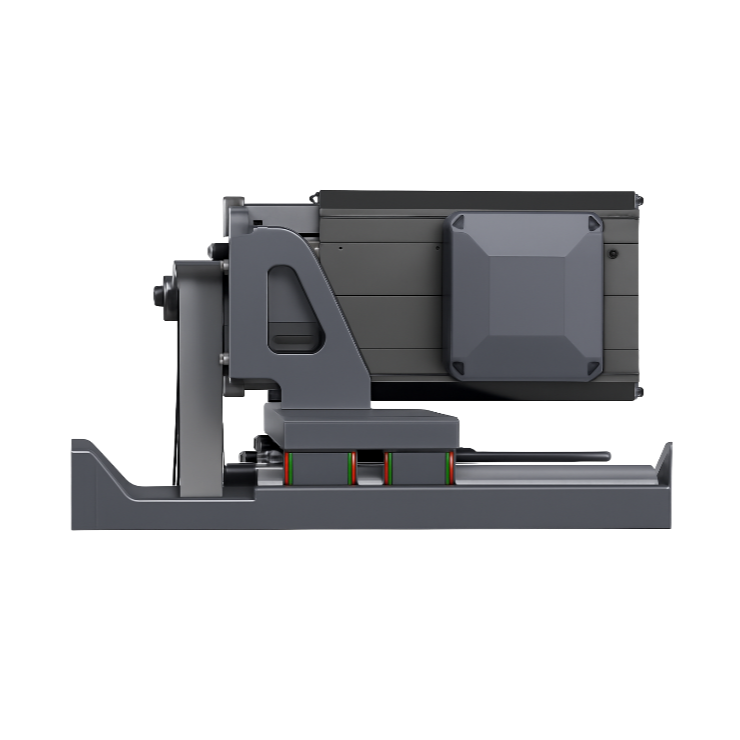

Topstar’s TEII series of electric injection molding machines goes a step further. Based on a dual platform (TE II all-electric and h-TE II hybrid), this series balances extremely high precision with flexible efficiency. Designed specifically to address the pain points of precision parts manufacturers, it offers stable mold protection, consistent clamping, and adaptability to a wide range of materials.

TEII Series All-Electric Injection Molding Machine: All-Electric Precision, Hybrid Flexibility

The TEII series solves this problem with two interchangeable platforms—TE II (all-electric) and h-TE II (hybrid)—so you pay only for the features you need for your production.

The TE II all-electric platform is suitable for operations requiring extremely high precision: medical device parts, microelectronic products, or parts with extremely tight tolerances (±0.02mm). Each part—clamping, injection, screw rotation—is driven by a servo motor, eliminating the “backlash” of hydraulic oil and achieving repeatability accuracy of ±0.1mm.

The h-TE II hybrid platform combines electric precision with hydraulic power, making it suitable for high-torque applications (e.g., thick-walled automotive sensors in the 200T model). Its clamping axis uses a servo-hydraulic system for a robust and stable lock, while injection and ejection remain electric to ensure accuracy. This reduces energy consumption by 40% compared to a fully hydraulic machine. These platforms are unique in that they share core components: the same high-rigidity mold design, modular injection unit, and control system. This means that if your production direction changes, you can upgrade from the TE II to the h-TE II with just a simple servo-hydraulic kit.

High-rigidity clamping: stability, protecting the mold and parts

For precision parts, clamping stability is crucial. Mold wobble can cause part deformation, mold cavity wear, and increased scrap rates. These all-electric injection molding machines effectively solve this problem with their clamping units, which are constructed from high-rigidity steel mold plates. Under full load, the mold plate deforms by less than 0.02mm.

Here is its practical application: Traditional electric injection molding machines use thin mold plates, which can deform by up to 0.05mm during clamping. For a 100mm wide part, this deformation can create a 0.03mm gap between the two halves of the mold—enough to cause flash or uneven wall thickness. The TEII’s 12mm-thick stress-relieving steel mold plate completely solves this problem: We tested a 150T TE II with a dual-cavity medical mold, and the cavity pressure sensors recorded no uneven stress over 5000 cycles. Mold protection is another key feature. The TEII’s servo-driven clamping device uses force feedback sensors to detect obstacles within 0.01 seconds and stops movement before damage occurs.

Linear Guides: Lighter Movement, Faster Cycle Speeds

Precision does not mean slower speed. The TEII series all-electric injection molding machines offer an optional linear guide system for the clamping unit. Linear guides reduce friction by 60%, allowing the clamping platen to move smoothly and avoiding “stick-slip.” This can reduce cycle time for small, precision parts by 5% to 10%. A microelectronics manufacturer used a 90T TE II electric injection molding machine equipped with linear guides to produce two mm-diameter connector pins; its processing cycle time was reduced from 8.2 seconds to 7.5 seconds, allowing an additional 1200 parts per shift.

Linear guides also improve the durability of the injection molding machine. Sliding guides wear down over time, requiring monthly lubrication and annual replacement. TEII’s linear guides, made of hardened steel and sealed bearings, offer a service life up to 5 times longer, a particularly valuable solution for high-volume precision injection molding. For example, a 200T h-TE II machine tool equipped with linear guides, operating 24/7 to produce automotive sensors, can produce over 3,000 more parts per week compared to the same machine tool equipped with sliding guides. Moreover, because linear guides maintain alignment better, scrap rates remain low even at high speeds.

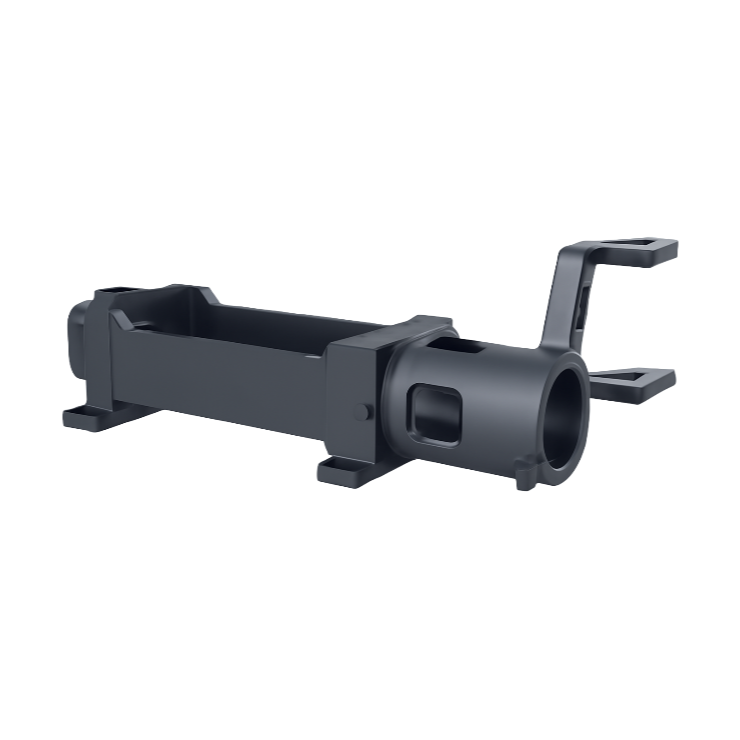

Modular Injection Molding Unit: Adaptable to Various Precision Machining Needs

The modular injection molding unit of the TEII series all-electric injection molding machines can adapt to a wide range of materials—from rigid PEEK for medical devices to flexible TPE for electronic seals—without requiring extensive reassembly.

At the heart of this unit is a quick-change screw and barrel system. A 25mm screw can be replaced with a 30mm screw in just 20 minutes, making it suitable for various high-volume processing, or a standard screw can be replaced with a barrier screw. A medical device manufacturer uses this system to easily switch between PEEK surgical instrument handles and PP syringe barrels on the same 120T TE II injection molding machine, saving 80 production hours of reassembly time per month.

The injection molding unit is also equipped with a servo-driven screw rotation device, enabling 1000-level speed control. This is crucial for materials such as glass fiber reinforced nylon, which require gentle mixing to avoid fiber breakage. The TEII’s precise speed control reduces fiber breakage rates by 70%, surpassing hydraulic injection molding machines and increasing part strength by 15%.

TEII Series All-Electric Injection Molding Machine: Case Study

An aerospace supplier that manufactures 10mm-diameter sensor housings for aircraft engines had extremely stringent requirements: tolerances of ±0.015mm, surface-defect-free production, and 24/7 operation. Their existing hydraulic injection molding machine could not meet these demands, resulting in a scrap rate of up to 9% and frequent missed delivery deadlines.

Topstar recommended the 150-ton TE II all-electric injection molding machine, equipped with linear guides and a barrier screw. Here are the results after 60 days:

- Scrap rate reduced from 9% to 0.8%

- Cycle time reduced from 11 seconds to 9.5 seconds, increasing output by 16%.

- Operator training time reduced by 50%, allowing them to add two new operators without impacting production.

- Mold wear reduced by 40%.

TEII Series Enables Precision Plastic Product Manufacturing

Precision plastic parts manufacturing is a balancing act: you need tight tolerances, fast production cycles, and extremely low scrap rates—while also protecting expensive molds and keeping operators highly efficient. The Topstar TEII series all-electric injection molding machines achieve this balance perfectly with their dual-platform design, high-rigidity clamping, modular injection units, and user-friendly interface. Compared to hydraulic injection molding machines, TEII users have seen an average 65% reduction in scrap rate, a 12% reduction in production cycle time, and a 40% reduction in energy costs.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/11/28

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/11/28

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/11/28

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/11/28

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar