Servo-driven injection molding machine for easier connector demolding: 20% increase in ejector thrust

2025/12/08 By le zhan

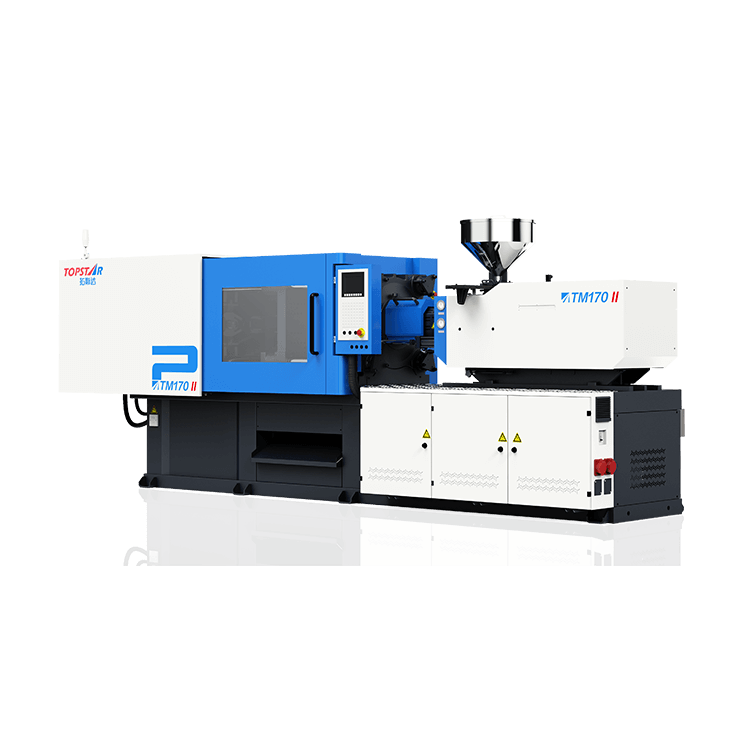

A consumer electronics miniature connector manufacturer found that their existing hydraulic injection molding machine couldn’t generate enough stable ejection force to eject high-precision USB-C connectors smoothly. 12% of their monthly production was scrap—parts stuck in the mold, pins bent, shells cracked—due to either a malfunctioning ejection mechanism or excessive ejection force. Clearly, this was due to insufficient ejection thrust from their injection molding machine. After selecting a Topstar servo-driven injection molding machine, the ejection thrust increased by 20% compared to the standard model, allowing the connector to be cleanly and precisely ejected while avoiding damage. Therefore, we will tell you how Topstar’s servo-driven injection molding machine solved the biggest demolding problem.

The Problem of Connector Demolding in Injection Molding

Connectors and plug-in products are among the most demanding in injection molding applications—they are small, complex, and require extremely tight tolerances. The design of these products makes demolding a significant challenge: thin walls easily adhere to the mold surface, locking mechanisms require overlocking, and there are fragile parts such as pins or terminals. However, most manufacturers, when purchasing a injection molding machine, often focus only on injection speed or clamping force, neglecting the performance of the ejector, the final and most critical step in the production process.

Our market research found that 52% of manufacturers cited demolding issues as their most significant pain point in production, ranking above machine downtime and material waste. Traditional machines account for 78% of demolding failures, with hydraulic ejectors providing inconsistent thrust, either peaking prematurely or rapidly diminishing mid-stroke. The problem isn’t just about thrust, but also about control. Connectors require “just the right” ejector performance: sufficient thrust to remove parts from the mold, yet with a smooth, adjustable speed to avoid impact damage.

Topstar’s Servo-Driven Injection Molding Machine: 20% Increased Ejection Thrust

Topstar’s TMⅡ servo-driven injection molding machines come standard with a 20% upgrade in ejection thrust. This isn’t just about increased power, but more importantly, about controllable power.

First, we upgraded the existing motor to a high-torque servo motor and a precision helical gear transmission, reducing energy loss by 12%. The direct result is a jump in ejection thrust from 5000 Newtons to 6000 Newtons on our 300-ton machine—enough to handle glass fiber reinforced nylon connectors.

However, without stability, mere thrust is meaningless. Therefore, our TMⅡ servo-driven injection molding machine employs closed-loop feedback, with over 10 sensors monitoring the ejector’s position, speed, and thrust 1000 times per second, adjusting the servo motor in real time. This means that each cycle delivers precisely the thrust you set—no more deviations. This 20% upgrade also shortens cycle time. Because the servo motor can accelerate and decelerate smoothly, eliminating the “jerkiness” typical in hydraulic systems, the ejector stroke is faster.

Features Designed Specifically for Connector Injection Molding

We not only increased the ejection thrust by 20%, but also incorporated three features designed and optimized for specific connector challenges.

- Adjustable Ejection Speed

Connectors come in a wide variety—from miniature 2mm board-to-board connectors to rugged industrial plugs. Topstar’s servo-driven injection molding machines allow you to adjust the ejection speed from 0.1 mm/s to 150 mm/s.

- Multi-Stage Ejection Profiles

Many connectors have undercuts, requiring a two-step ejection process: first, a gentle pull to release the undercut, then a complete ejection to pop the part out. This servo-driven injection molding machine stores over 100 custom ejection profiles—you can program the first stage to release the undercut and then the second stage to complete it.

- Mold Protection Sensor

Even with perfect thrust, a contaminated mold or a deformed part can cause jamming. Our servo-driven injection molding machine has a built-in mold protection function: if the ejector encounters resistance 10% higher than expected, it immediately reverses and stops the cycle, alerting the operator via the human-machine interface (HMI) screen.

Case Studies of Connector Production Using a Servo-Driven Injection Molding Machine

While data is essential, real-world customer case studies better demonstrate how a 20% increase in ejection force can fundamentally transform production operations. Below are three case studies from Topstar customers, covering the consumer electronics, automotive, and medical connector sectors.

Case Study 1: Consumer Electronics

Challenge: Due to unstable ejection force, the scrap rate for USB-C connectors reached 12%; mold disassembly was required 2-3 times per week. Solution: Topstar TMⅡ300T servo-driven injection molding machine. Results: Scrap rate reduced to 3%; no mold disassembly required; cycle time reduced by 0.6 seconds.

Case Study 2: Automotive Industry

Challenge: Glass fiber-reinforced nylon automotive pin headers got stuck in the mold, resulting in an 8% scrap rate and 1-hour delays per jam. Solution: Topstar TMⅡ300T servo-driven injection molding machine. Results: Scrap rate reduced to 0.5%; output increased by 22%.

Case Study 3: Medical Industry

Challenge: A 2mm-precision medical connector broke during ejection; inconsistent manufacturing processes raised concerns about FDA approval. Solution: Topstar TMⅡ200 servo-driven injection molding machine with a multi-stage ejection mechanism. Results: Scrap rate reduced to 0.8%; consistent process data met FDA standards.

The key to connector injection molding lies in precise ejection thrust

Smaller parts, tighter tolerances, faster production speeds, and lower costs. Traditional injection molding machines cannot meet these demands, trapped in a vicious cycle of scrap, delays, and mold damage. Topstar’s servo-driven injection molding machine, with 20% more ejection thrust, effectively solves this problem. It allows the injection molding machine to focus more on the most critical step: cleanly, quickly, and reliably removing parts from the mold.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/12/08

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/12/08

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/12/08

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/12/08

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar