How to choose the right auto loader to meet the material conveying needs of injection molding?

2026/01/21 By le zhan

A suitable auto loader directly impacts the output, product quality, and uptime of an injection molding production line. An unsuitable feeder of the wrong size or specifications can lead to insufficient material supply, contamination, increased maintenance costs, and lost production time. A suitable auto loader seamlessly integrates into the production process, reliably delivering clean granules, reducing dust and material degradation, and maintaining mold cycle stability. If you’re unsure how to choose an auto loader, this guide compares the different types of feeders in the Topstar TAL series to help you select the best auto loaders for your injection molding needs.

Assess production needs and material characteristics

First, clearly define your actual needs. The first step in correctly selecting an auto loader is knowing what tasks it needs to perform.

Productivity and throughput requirements assessment: First, calculate the required material throughput per machine per hour based on cycle time, injection weight, and planned utilization. Then, for centralized feeding to multiple machines, sum the individual requirements and finally add an appropriate margin (typically 10–30%) to accommodate peak loads and future expansion.

Material type: PP, PE, ABS, and PS have good flowability and are suitable for all kinds of autoloaders. High-viscosity or hygroscopic materials (PA, PET, PC) may require controlled, gentle feeding methods and close integration with the drying process. For hygroscopic resins, minimise residence time and ensure the loader supports direct feeding to the dehumidifying dryer. Furthermore, recycled and reground materials often produce more fines and dust, which can clog narrow feed openings. Therefore, a removable automatic feeding machine equipped with a powerful filter and optional cyclone separator is necessary.

Conveying Distance and Layout Limitations:

Short-distance, machine-mounted loading (0-2 meters) is best suited for single automatic feeders mounted directly on the injection moulding machine. Long-distance conveying (up to 10 meters) or centralized material rooms require detachable auto loaders with larger fan capacity and remote master controllers.

Environmental and Cleanliness Requirements:

For medical, food-contact, or cleanroom applications, manufacturers require all-stainless-steel construction, hygienic design, and extremely low particulate generation. Topstar’s stainless steel construction and dual-layer filtration system meet these needs. Additionally, for materials with high dust content or operations requiring high hygiene standards, it is recommended to consider an open, detachable auto loader equipped with a cyclone separator and a separate dust collection bin to reduce the load on the filters.

Single Auto Loaders – Compact loader

The single auto loader features a compact design that allows operators to mount it directly on or next to the injection molding machine. If you need a clean, efficient, and space-saving auto loader to meet the feeding needs of a single machine, this product is ideal.

Key Features and Benefits:

Compact Stainless Steel Construction: This minimizes the risk of contamination while facilitating hygienic handling of granular materials. In addition, the stainless steel surface prevents corrosion and keeps the material clean for extended periods.

Motor Protection System: Prevents overload and thermal damage, extending service life. This is especially important for 24/7 continuous production lines.

Dual-Layer Filtration: Combines a fabric filter and a stainless steel mesh to capture dust while extending filter life effectively. This reduces the downtime required for filter replacement.

Motor Reverse Dust Removal: Periodic reverse airflow automatically removes accumulated dust from the filter, maintaining suction performance and reducing manual cleaning.

Integrated Smart Sensing and Alarms: Level sensors in the hopper and receiver accurately detect the presence of material and automatically alarm when material is insufficient; this reduces manual checks and prevents material shortages.

When to Choose a Standalone Auto Loader:

When you need to feed a single injection molding machine directly with minimal piping and the shortest distance, and when space around the molding unit is limited, you need a simple, integrated material-handling solution on the machine. This also includes standard granules or masterbatches with low fine-powder content, high cleanliness requirements, and a preference for a stainless-steel casing. A standalone automatic feeder can be selected.

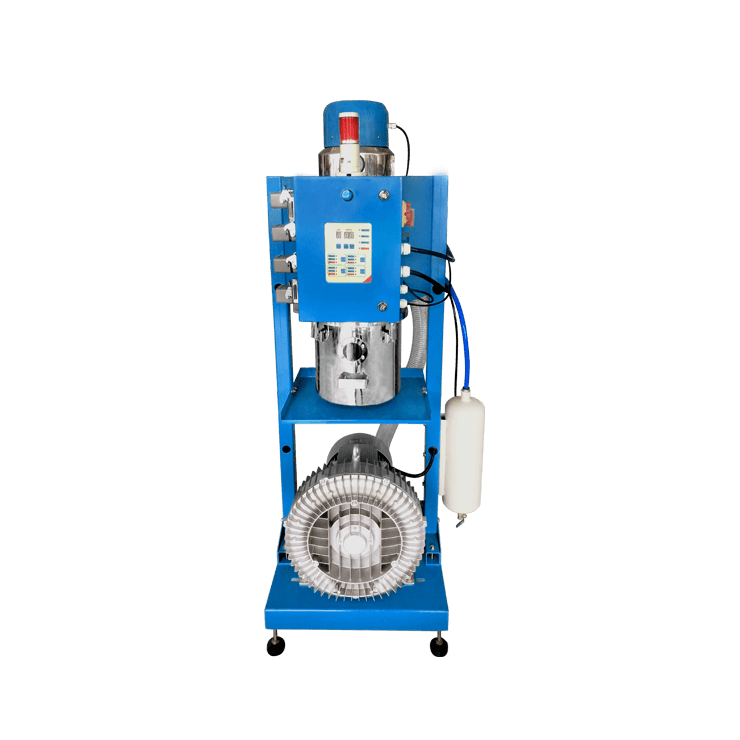

Detachable Auto Loader – for Multi-Hopper Receiver Systems

When your production needs exceed the feeding capacity of a single machine or require centralized material distribution, a detachable auto loader offers scalability, safety, and enhanced conveying capabilities.

Design and Capacity Highlights:

Separable Main Controller and Hopper Receivers: The system mounts the controller remotely and installs multiple hopper receivers near the machine for material collection. This one-to-many topology supports a centralized material room and centralized control.

High Conveying Capacity: Depending on pipe diameter, height, and material characteristics, each model offers conveying capacities up to 700 kg/hour. This capacity makes it suitable for medium to high-flow operations.

Maximum Loading Distance of 10 Meters: The detachable design supports longer pipe runs in compact factory layouts and allows for flexible routing of pipes to multiple molding units.

Independent Filtration and Optional Cyclone Separator: The material auto loader’s filtration reduces dust load on the filter, while the optional cyclone separator pre-collects delicate and heavy powders for easier maintenance.

When to Choose a Detachable Auto Loader:

Choose a detachable auto loader when you operate multiple injection molding machines, have medium to high capacity requirements, need centralized material control, require flexibility to reallocate receivers based on production changes, handle materials with high dust content, or require more potent suction and cyclone pre-separation for recycled materials.

Open Type Detachable Auto Loader – Efficient Dust Management and Industrial Design

The open type detachable auto loader utilizes European industrial design principles for efficient, low-dust conveying.

Core Design Features:

Downward Suction Airflow with Cyclone Separator Baffle: Instead of directly depositing dust on the filter, the airflow uses centrifugal force to separate heavier particles, which fall into a separate dust collection bin. This significantly reduces the filter load and extends filter life.

Independent Dust Collection Bin: Easy to access and empty; reduces dust exposure during maintenance and improves cleanliness.

Stainless Steel Construction and Aesthetic Design: Suitable for visible production areas or showrooms where operator comfort and factory presentation are essential. Single-stage or dual-stage blower options: Choose a single-stage blower for standard conveying; a dual-stage blower provides higher suction and pressure for longer conveying distances or heavier materials.

Compatible with multiple hopper configurations: Supports single and multi-hopper receiver layouts with flexible piping and control capabilities.

Operational Advantages:

Reduced long-term maintenance costs: Cyclone separation and reduced filter load minimize cleaning frequency and extend the lifespan of consumables.

Stable long-term performance: With pre-separation protected filters, the open type auto loader maintains suction efficiency during long shifts and heavy-duty cycles.

Visual and environmental appeal: A clean appearance and reduced dust emissions contribute to lean manufacturing and a cleaner workspace.

Topstar’s open type detachable auto loader is designed to meet demanding material handling needs: robust, hygienic, and engineered for reliable operation over long periods in demanding injection molding environments.

Choosing the Right Automatic Loader for You

For production lines with limited space or operational constraints, a single auto loader is a simple and cost-effective option. Alternatively, for medium-to-large-scale production operations requiring centralized material distribution or handling of recycled materials, a detachable auto loader equipped with a cyclone separator can be chosen to reduce dust load and increase productivity. Furthermore, for heavy-duty applications, areas with high aesthetic requirements, or hygiene-sensitive production zones, an open type detachable auto loader offers superior dust control, an aesthetically pleasing appearance, and long-term stability. Choosing the right automatic loader is more than just matching parameters on a data sheet; it’s about aligning your actual production conditions and material characteristics with the design advantages of the loader.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2026/01/21

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2026/01/21

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2026/01/21

- What factors can cause delays in the injection molding process of plastic molding machine? 2026/01/21

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- cabinet dryer

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- injection moulding dryer

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar