Why does the high-speed packaging industry need plastic injection machine?

2025/05/10 By Topstar

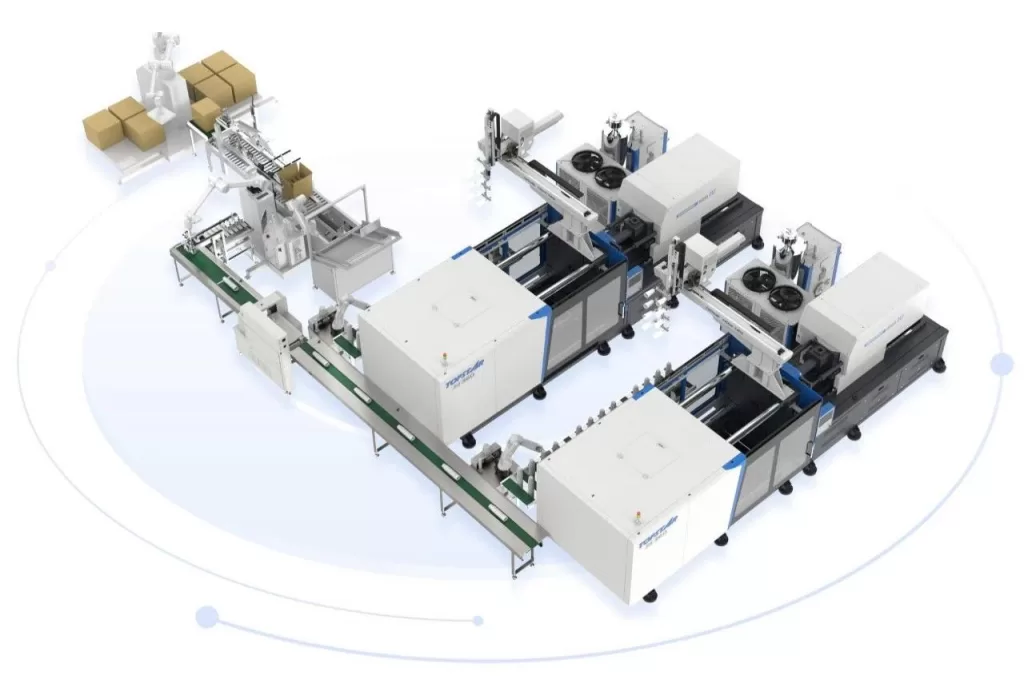

Deeply influenced by Chinese tea brands, the global tea market has shown a comprehensive and substantial growth. In 2024 alone, the scale of China’s new tea industry has exceeded RMB 300 billion, and is expected to exceed RMB 400 billion by 2028. This growth has driven the simultaneous expansion of milk tea packaging, especially milk tea cups, cup lids, and other outer packaging produced by a plastic injection machine. The demand for these packages requires fast-response manufacturing capabilities, high output rates, and the integration of high-speed automated production lines. To meet these needs, Topstar provides injection molding automation production line solutions for the high-speed packaging industry, combining the high-speed electric drive, modular automation, and remote monitoring functions of plastic injection machines to support the tight production rhythm of the milk tea industry.

Fast and precise production using a plastic injection machine

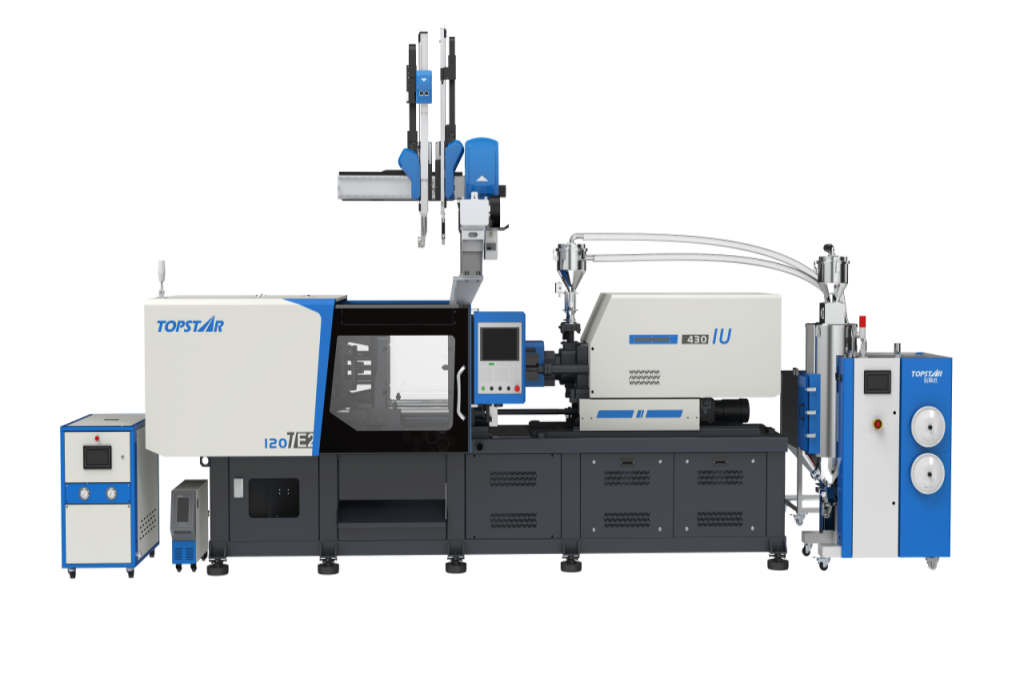

High-speed packaging production requires both output and precision. The high-speed all electric injection molding machine can well reflect this balance in this solution. With an eight-cavity mold and a fast cycle of 7.2 seconds, each plastic injection machine can produce more than 14,400 milk tea cups per day, more than 15% higher than the output of traditional machines. In addition, when operators run multiple devices in parallel, they can linearly expand the output to flexibly cope with the peak season.

In addition to delivering strong output, this plastic injection machine ensures dimensional accuracy, enabling it to produce leak-free cup lids and maintain consistent cup wall thickness. Its discrete intelligent drive injection unit optimizes melt flow and holding pressure to produce uniform, consistent packaging products that meet strict beverage safety regulations.

Modular design for increased flexibility

To solve the problems of surging order volume, complex equipment in the production workshop, and space constraints, Topstar’s plastic injection machines adopt an integrated modular design, reducing the factory footprint by up to 50%, allowing operators to change settings flexibly. The compact injection molding unit, servo-driven robots, and auxiliary equipment can connect seamlessly with the plastic injection molding machine without large-scale factory modifications or additional infrastructure.

At the same time, the modular architecture can also support rapid reconfiguration, without much downtime to switch from cup production to lid or other injection molding machine-based packaging component production. This flexibility enables manufacturers to quickly adapt to changing product lines or promotional packaging needs and maximize equipment utilization.

Smart trajectories bring automated production.

In the high-speed packaging industry, uninterrupted operation is required to ensure output. Intelligent trajectory control of manipulators and robots is integrated into the injection molding automation production line solution to ensure that parts disassembly, post-processing, and assembly are carried out simultaneously, to monitor cycle changes in real time, dynamically adjust the robot path, ensure seamless handover, and prevent production line downtime. Through a unified communication language, plastic injection machines can continuously share performance data with the central control system to achieve predictive maintenance, minimize unplanned downtime, avoid costly delays, and maintain product supply during peak demand.

Remote monitoring and intelligent maintenance

Topstar’s plastic injection machine ecosystem provides cloud-based remote operation and maintenance, allowing operators to instantly view machine status, cycle times, and energy consumption anytime, anywhere. The real-time dashboard highlights abnormal conditions such as pressure deviation or temperature drift, allowing operators to take diagnostic measures quickly before defects occur.

This intelligent maintenance framework reduces labor costs and extends the service life of key components. Both heaters and servo motors can receive data-driven life cycle recommendations to ensure that each injection molding machine can operate optimally. Thus, engineers create a robust and scalable injection molding solution for the high-speed packaging industry.

Each plastic injection molding machine can produce 100,000 pieces per day.

Under normal conditions, a single-speed electric injection molding machine can produce more than 100,000 milk tea cups daily. Manufacturers can increase the output of production facilities by up to 20% by combining multi-cavity molds, fast injection molding control, and synchronous automation. These powerful indicators enable the high-speed packaging industry to meet unprecedented peaks in consumer demand and quickly launch new products. In addition, the precision molding capabilities of plastic injection molding machines minimize material waste and shorten molding cycles, thereby reducing unit costs. In the labor-intensive and profit-sensitive beverage industry, they will translate into a competitive advantage.

Comprehensive solutions for high-speed packaging

The trend of large-scale growth in milk tea cups highlights the need for the high-speed packaging industry to adopt advanced injection molding machine technology. Using fast electric drives, modular system design, intelligent automation, and remote maintenance in Topstar’s injection molding automation production line solutions can solve key pain points from production scale to quality consistency. Manufacturers can easily cope with peak season pressures by leveraging these features and achieve product diversification.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/05/10

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/05/10

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/05/10

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/05/10

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- cabinet dryer

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- injection moulding dryer

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar