Digital Control Platform: Selecting Topstar Electric Injection Molding Machine for Smart Injection Molding

2023/09/28 By topstar

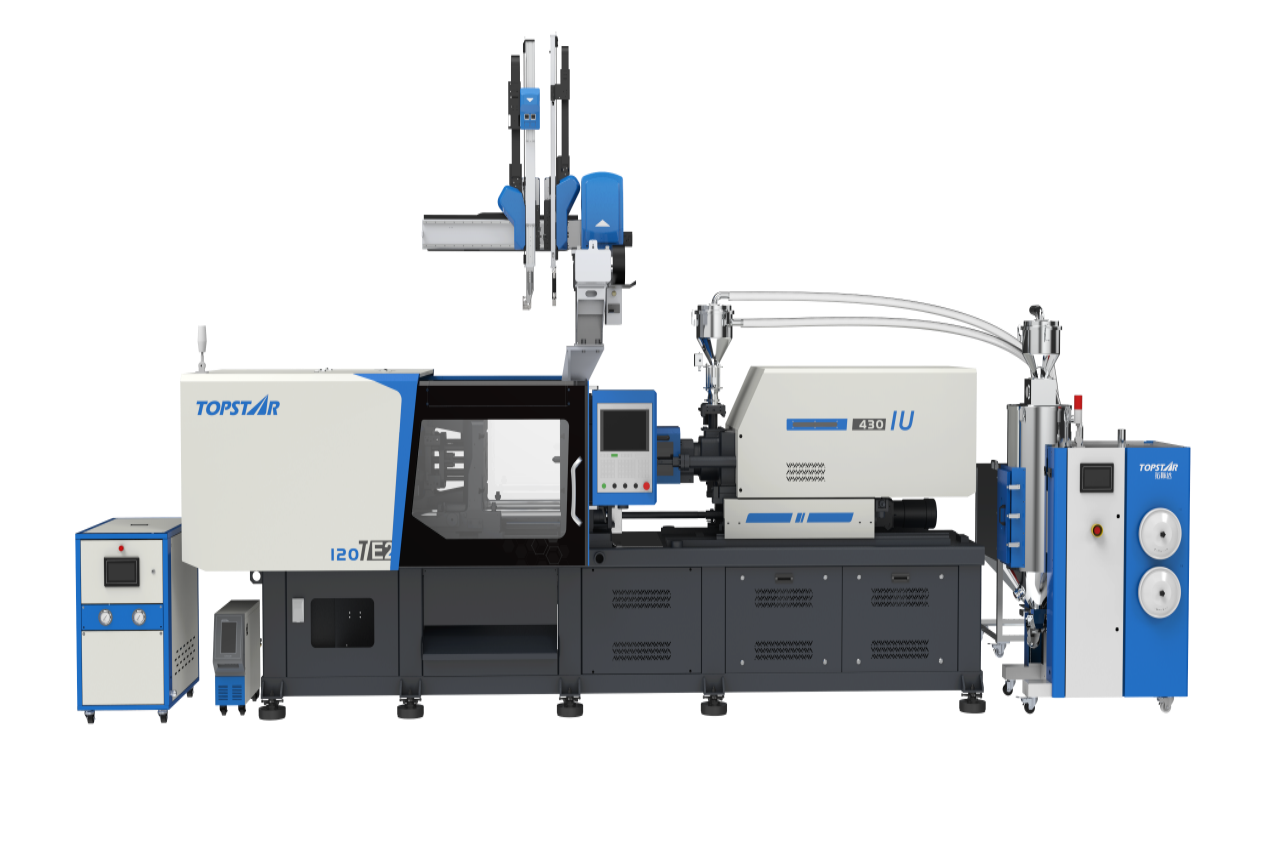

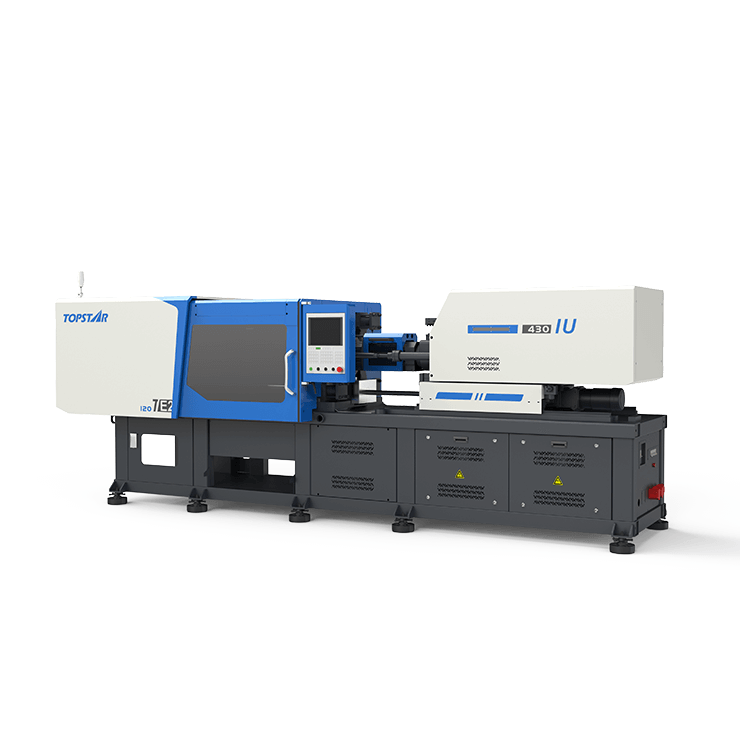

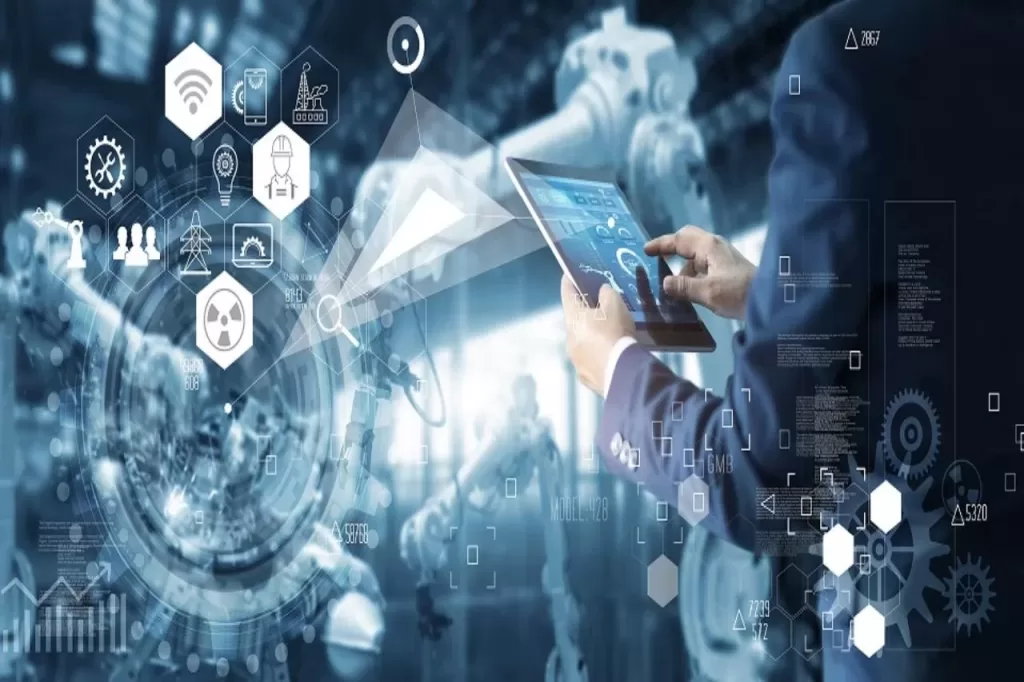

Factories equipped with digital control platforms are not just about becoming smarter; they’re about transforming. For injection molding, electric injection molding machine and control systems controlled by digital platforms can reduce production cycle fluctuations, improve first-pass yield, and turn raw production data into actionable insights. When you’re in production, an injection unit can promptly inform you when the mold is out of tolerance, automatically adjust the process before scrap is generated, and record each cycle for traceability. This is the effect of electric injection molding machines equipped with modern digital control platforms. Topstar’s electric injection molding machine delivers connectivity, precision, and data management capabilities that industrial teams need, enabling them to shift from reactive troubleshooting to proactive, data-driven production management.

Why Digital Control Platforms Can Transform Injection Molding Production

Digital control is more than just replacing knobs with screens—it changes the way you control. Traditional analog or semi-electronic systems limit the speed and precision of feedback loops. Electric injection molding machines equipped with digital control platforms enable high-speed data exchange between servo drives, pressure/temperature controllers, and the machine’s central logic. This enables rigorous closed-loop control of key parameters, including injection speed, screw position, melt pressure, and holding pressure. The direct result is improved cycle consistency and a narrower process window.

Furthermore, the digital controller enables complex control strategies: multi-stage injection profiles, cavity pressure-based switching, adaptive screw recovery, and dynamic compensation for environmental or material variations. When the various subsystems (injection unit, mold clamping control, auxiliary equipment, and mold temperature controller) work together, the machine can respond to transient disturbances in milliseconds rather than seconds. For manufacturers, this means fewer defects, more predictable mold filling, and greater processing capabilities to handle tighter tolerances.

Architecture and Communication of Collaborative Controlled Electric Injection Molding Machine

Choosing a Topstar electric injection molding machine means evaluating the machine’s architecture: controller, drives, sensors, human-machine interface (HMI), and network layer. Topstar’s all-electric design utilizes high-performance servo drives and a central digital controller to coordinate motion and process loops. Key features include deterministic communication channels (industrial Ethernet or fieldbus), fast analog/digital I/O for sensor sampling, and a human-machine interface (HMI) supporting recipe management, visualization, and remote access. Simultaneously, it ensures high-speed data transmission between control units and the consistent sharing of status information from pressure sensors, encoder positions, and auxiliary actuators. This synchronized data enables control logic to execute coordinated actions, thereby reducing mechanical stress and shortening cycle times. These architectural elements determine the efficiency with which electric injection molding machines function in the broader digital factory.

Real-time Monitoring and Support for Management Decisions

Data collection without actionable insights is meaningless—Topstar electric injection molding machines fill this gap with their digital control platform, enabling real-time monitoring and rapid decision-making through process integration. The injection molding machine‘s intuitive Human-Machine Interface (HMI) displays key production data, including equipment status, cycle time, defect rate, and energy consumption, on a centralized dashboard accessible via an onboard touchscreen or remote equipment. Managers can set custom alerts for anomalies, allowing for immediate adjustments before defects escalate.

For example, a packaging manufacturer using Topstar electric injection molding machines to produce thin-walled bottles received an alert about extended cooling times, discovered a blockage in the cooling channels, and resolved the issue within 15 minutes. This injection molding machine can also collect historical data, enabling managers to analyze trends in Overall Equipment Effectiveness (OEE) and energy consumption, thereby optimizing resource allocation.

Topstar Electric Injection Molding Machine Empowers Enterprise Digital Transformation

True digital transformation requires interconnected systems, not data silos. Topstar’s electric injection molding machine’s digital control platform enables seamless sharing of production data within the enterprise. This injection molding machine integrates with Manufacturing Execution Systems (MES) and Quality Management Systems, ensuring unimpeded flow of production data from the shop floor to management. For example, after the electric injection molding machine completes a batch of products, data such as output, defect rate, and material usage are automatically synchronized to the ERP system, updating inventory and order status in real time. This integration eliminates manual data entry errors and accelerates order fulfillment.

Furthermore, under a unified control system, the electric injection molding machine supports multi-device data sharing, allowing access to real-time data from multiple devices. By achieving seamless data integration, Topstar electric injection molding machines become key equipment for your enterprise’s digital transformation.

Facilitating Cost Savings

Topstar’s digital control platform for electric injection molding machines optimizes resource utilization by translating data insights into tangible cost savings. Energy waste is a major pain point in injection molding operations—traditional injection molding machines consume excessive electricity during idle or inefficient cycles. Topstar’s platform monitors energy usage in real time, identifies waste patterns, and provides corresponding adjustment suggestions. For example, the platform can automatically reduce servo motor speed during cooling cycles, resulting in a 35% reduction in energy consumption compared to traditional injection molding machines. More importantly, they can also optimize workforce resources by automating routine tasks such as parameter adjustments and data logging, allowing operators to focus on technical tasks. This not only saves costs but also increases team productivity.

Your Partner for Smart Injection Molding

Smart injection molding is not about technology for technology’s sake, but about using data to solve real-world problems. Topstar’s digital control platform for electric injection molding machines is based on this philosophy, integrating high-speed data transmission, precise parameter control, real-time insights, and seamless integration to revolutionize your injection molding operations. Whether you are a small business focused on improving precision or a large enterprise seeking mass production, Topstar electric injection molding machines offer digital capabilities to meet your needs. They also lay the foundation for the digital transformation of injection molding companies.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2023/09/28

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2023/09/28

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2023/09/28

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/09/28

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar