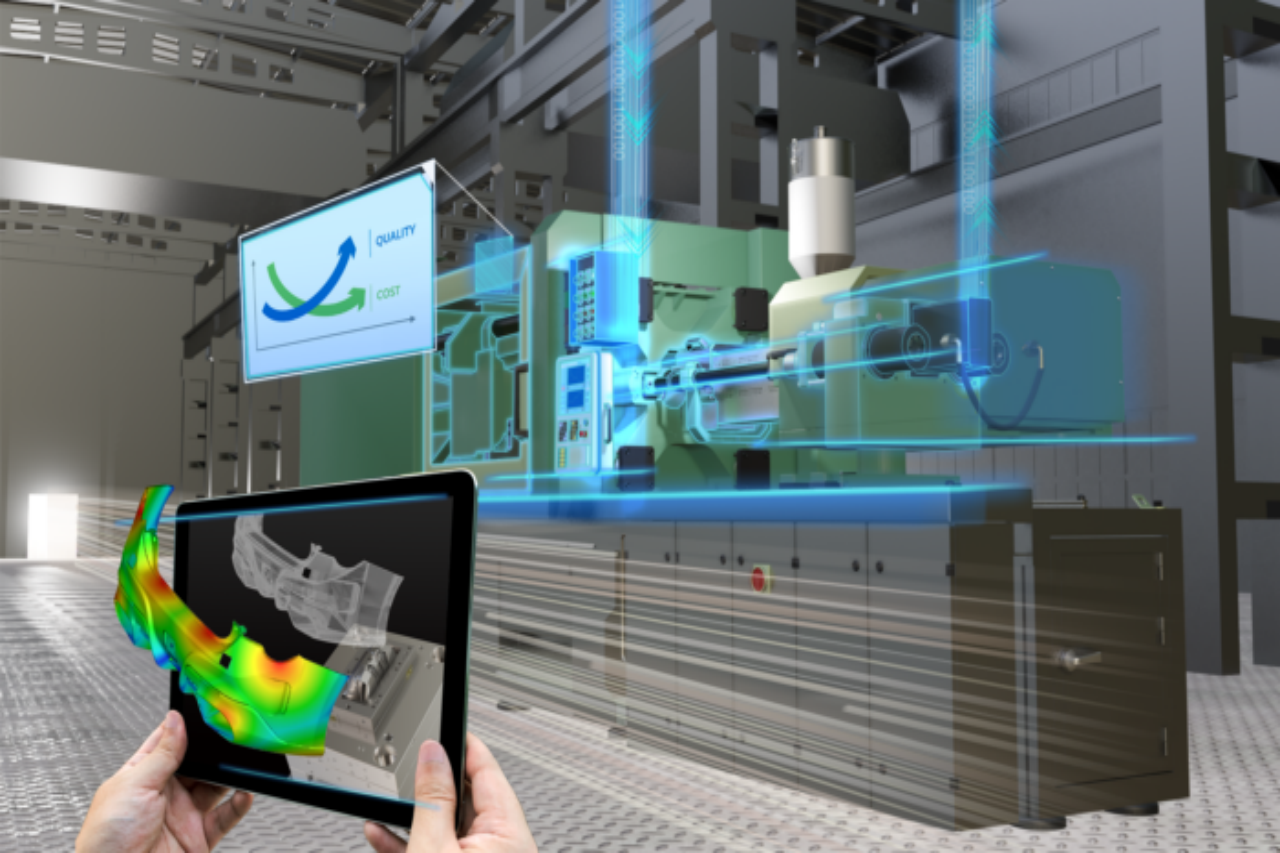

Digital Platform All Electric Injection Molding Machine: Enhance Efficiency & Parameter Control

2025/10/27 By le zhan

Manufacturers across many regions lose 15% to 20% of their production time due to communication delays and parameter loss in traditional hydraulic or basic electric injection molding machines. For a 24/7 factory, this translates to 1,080 hours of wasted production annually and millions of dollars in lost revenue. Even worse, 4% to 8% of parts are scrapped due to inconsistent pressure, speed, or temperature control, costing each manufacturer tens of thousands of dollars annually. To address this inefficiency, Topstar has implemented digital platform control on all electric injection molding machine. By using digital control to enable rapid data transmission and employing discrete intelligent drive technology for real-time feedback, these machines can reduce injection molding cycle times by 15-25% and reduce scrap rates to below 2%.

Why Digital Platform Control Can Solve the Pain Points of Traditional Injection Molding

Traditional injection molding machines, whether hydraulic or electric, rely on decentralized control systems. Hydraulic machines use fluid pressure to drive movement, resulting in slow response times and imprecise parameter adjustments. While basic electric injection molding machines reduce liquid waste, they lack coordinated control between various units, such as injection, clamping, and ejection, resulting in communication delays exceeding 200 milliseconds during high-speed cycles. These deficiencies create two problems:

Parameter inconsistency: Pressure or speed drifts mid-cycle, resulting in inconsistent part dimensions.

Cycle time bloat: Delays between process steps can add seconds to each cycle, which, when accumulated, can ultimately lead to hours of wasted production time.

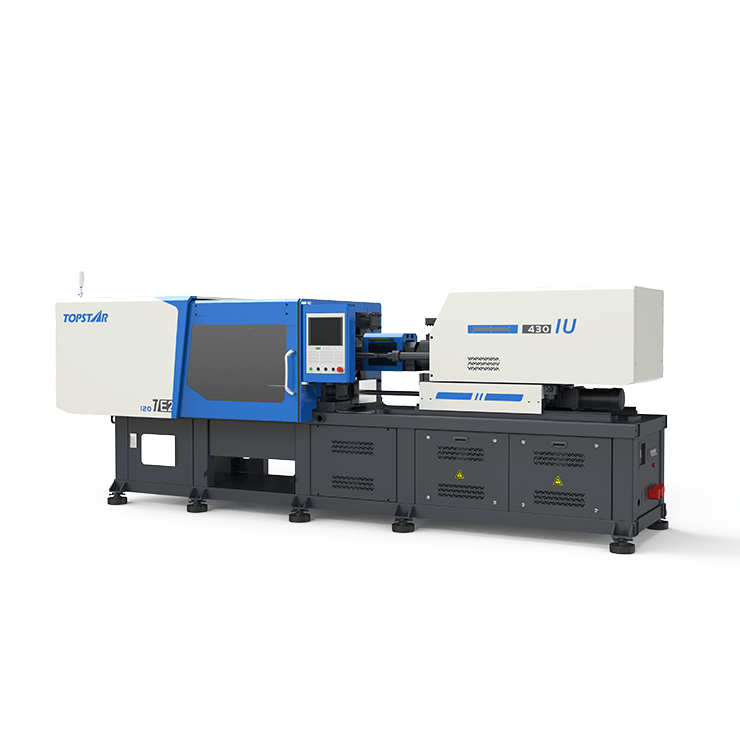

Topstar eliminates these problems with a digital platform in its all electric injection molding machines. Each control unit communicates via a high-speed bus, reducing communication delays to 20 milliseconds or less. A medical component manufacturer using our TEll injection molding machines stated, “After implementing Topstar’s digital control, our scrap rate has dropped to 1.1%, resulting in lower costs and higher efficiency.”

Fast Data and Coordinated Control of All Electric Injection Molding Machine

The digital control core of Topstar’s all electric injection molding machines integrates the injection molding process, creating a unified process unit and a digital framework for seamless operation.

Unified Data Transmission: Topstar connects the injection unit, clamping unit, ejection system, and temperature regulator via a unified control system with a communication protocol. This allows real-time data sharing between units, eliminating signal latency.

Coordinated Motion Control: Unlike traditional machines where each unit operates independently, Topstar’s system synchronizes each step. For example, the injection unit begins advancing when the clamp is nearly fully closed, reducing each cycle by 2-3 seconds.

Centralized Parameter Storage: All process parameters (injection speed, pressure, cooling time, clamping force) are stored in a digital library. Operators can call up preset recipes for different parts in seconds, reducing changeover time by 40% compared to manual adjustments on hydraulic presses.

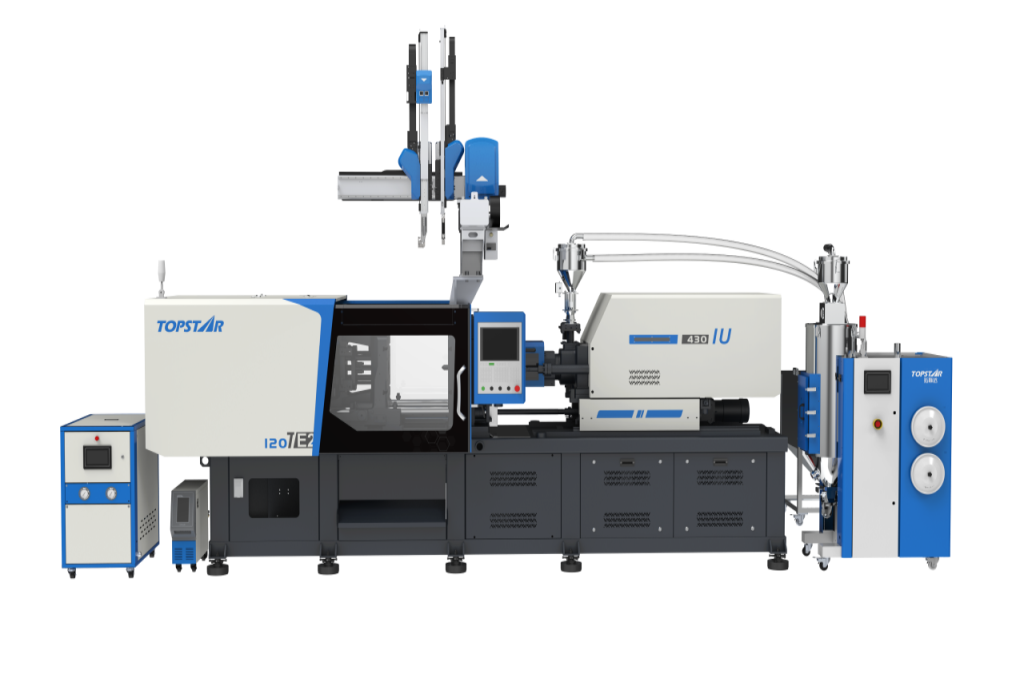

Practically speaking, this means that consumer product molders can now complete a changeover in 10 minutes when switching between three different plastic parts. This not only speeds up production but also reduces human error.

Reduce Delays and Maximize Precision in An All Electric Injection Molding Machine

To further improve efficiency, Topstar’s all electric injection molding machines utilize discrete intelligent drive control technology. Topstar connects servo motors directly to each process unit, bypassing intermediate components that cause delays. The results are as follows:

No Communication Latency: With other motors, drive signals pass through multiple controllers, increasing latency. Discrete intelligent drives send signals directly to servo motors, ensuring real-time adjustments to position, speed, and pressure (response time ≤ 10ms).

Optimized Motion Profiles: The system uses algorithms to customize speed and pressure profiles based on the material and part design. For example, it reduces injection speed near the end of the mold cavity to prevent burrs and then increases ejection speed to shorten cycle time—all automatically.

Energy Efficiency: Servo motors consume electricity only when in motion, reducing energy consumption by 30% to 40% compared to hydraulic injection molding machines. Discrete intelligent drives enable the injection molding machine to adapt to material variations, monitoring viscosity and adjusting injection pressure in real time.

Precise parameter monitoring improves quality consistency

The digital platform of the Topstar all electric injection molding machine not only controls parameters but also precisely monitors them, ensuring consistency across thousands of parts.

Injection speed and pressure: Monitored in increments of 0.1 mm/s and 0.1 MPa, respectively. This accuracy prevents under-injection and over-filling, both of which are the most common causes of scrap.

Temperature control: The heater zone (barrel, nozzle) is monitored with an accuracy of ±1°C, which is critical for materials like ABS that degrade at high temperatures or have poor flow properties at low temperatures.

All this data is recorded and accessible via the injection molding machine‘s touchscreen or MES system. This traceability supports compliance with quality standards (such as ISO 13485) required by industries like medical and automotive, as well as detailed process documentation.

Case Study

Let’s consider a packaging manufacturer producing 500ml PP plastic bottles (2-cavity mold, 28g per part):

Previous setup: Hydraulic injection molding machine (cycle time: 45 seconds, scrap rate: 6%, energy consumption: 12kWh/hour).

Topstar all electric injection molding machine: Cycle time: 38 seconds (15.5% reduction), scrap rate: 1.2% (80% reduction), energy consumption: 7.2kWh/hour (40% reduction).

Annual savings: 129,600 more parts produced, tens of thousands of dollars saved, and lower material scrap.

The manufacturer’s production manager concluded, “We used to run three shifts to meet demand. With Topstar’s injection molding machines, we can achieve the same output in two shifts, while also saving on labor costs. The digital control and discrete drive systems have transformed our production operations.”

How They Compare to Hydraulic and Other All Electric Injection Molding Machine

Here’s how Topstar’s digital platform all electric injection molding machines compare to other injection molding machines in the industry:

| Feature | Topstar Digital Platform All Electric Injection Molding Machine | Hydraulic Injection Molding Machine | Other Electric Injection Molding Machines |

| Cycle Time Reduction | 15–25% | 0% | 5–10% |

| Scrap Rate | <2% | 4–8% | 2–5% |

| Energy Use | 30–40% lower than hydraulic | Highest (constant pump operation) | 10–15% lower than hydraulic |

| Communication Delay | ≤20ms | 200+ms | 100–150ms |

| Parameter Precision | ±0.1mm/s (speed), ±0.1MPa (pressure) | ±1mm/s, ±1MPa | ±0.5mm/s, ±0.5MPa |

Digital Control for Future-Producing

For manufacturers tired of wasting time, materials, and energy, Topstar’s digital platform all electric injection molding machines can fundamentally solve these problems. Their integrated digital control eliminates communication delays, their discrete intelligent drives ensure real-time accuracy, and their comprehensive parameter monitoring enhances machine stability, while reducing costs and improving quality.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/10/27

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/10/27

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/10/27

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/10/27

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar