How to solve platen damage problems: High-rigidity platen design for electric injection molding machine

2025/11/10 By le zhan

Damage to the clamping platen in an electric injection molding machine can lead to unplanned downtime, parts scrap, and additional emergency repair costs. As an injection molding machine manufacturer, we recognize that the root cause lies in insufficient platen design strength, which cannot withstand the high precision and high-strength forces required by electric injection molding machines. Therefore, we employ high-rigidity clamping plates in our electric injection molding machines, built through comprehensive stress analysis and optimized design strength, fundamentally solving this problem.

Impact of Clamping Platen Damage in Electric Injection Molding Machine

The clamping platen is a core component of any injection molding machine, holding the mold in place during mold closing and injection. For electric injection molding machines, due to their faster mold closing speed, higher precision, and more stable pressure, the impact of clamping platen damage is more severe. If the clamping platen sustains damage, it will cause additional downtime, and technicians may take 3 to 21 days to repair or replace the damaged clamping platen. Furthermore, a warped or misaligned clamping platen can lead to uneven clamping pressure, resulting in flash, short shots, or dimensional errors. Most critically, a cracked clamping platen can cause catastrophic failure under clamping pressure, endangering operator safety and damaging expensive molds.

Clamping platen damage is not just a maintenance issue; it threatens your profits and poses production safety risks. For electric injection molding machines that rely on precision for performance, clamping platen damage negates all those advantages.

The Root Causes of Clamping Platen Damage in Electric Injection Molding Machine

The forces generated by electric injection molding machines differ from those of other injection molding machines, making them more prone to clamping platen damage. Understanding these reasons will show you why a high-rigidity design is necessary:

High Clamping Force Density: Electric injection molding machines use smaller, more compact actuators to provide clamping force, resulting in higher stress concentration on the clamping platen.

Rapid Clamping Speed: The electric servo motor accelerates the clamping platen, generating impact forces that a fragile platen cannot absorb.

Precision Requirements: Electric injection molding machines are typically used to process parts with tight tolerances, so even a 0.1 mm warpage of the clamping platen can lead to quality problems.

Thermal fatigue: The heating and cooling cycles of the mold cause repeated expansion and contraction of the platen, creating microcracks that can widen over time—especially on thin, poorly designed platens.

Mold misalignment: Even slight mold misalignment can cause uneven stress on the platen, leading to mold deformation or cracking.

A Topstar engineer noted, “We found that platen damage is most common on electric machines operating at high speeds 24/7. These machines were originally designed for hydraulic systems, not the precise, high-impact loads of electric systems.”

High-rigidity platens based on stress analysis

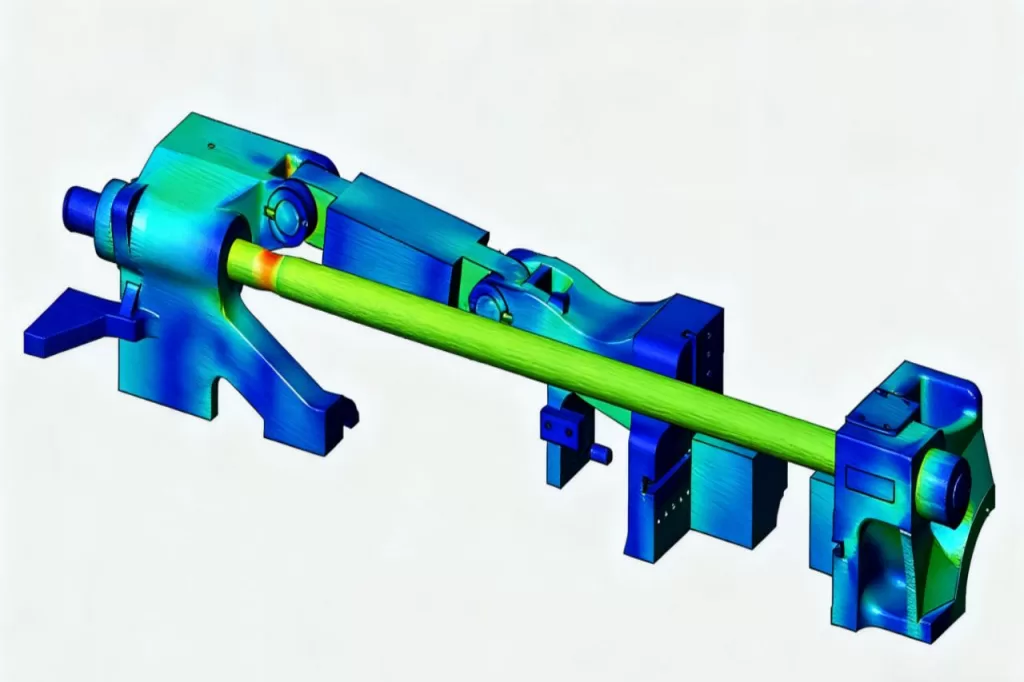

To address the platen damage issue, Topstar first conducted a comprehensive stress analysis, a crucial first step in designing a high-rigidity platen capable of withstanding the unique forces of an electric injection molding machine. Next, we used finite element analysis (FEA) software to simulate all the forces the platen would experience: clamping pressure, injection back pressure, rapid clamping impact, and thermal expansion. This allowed us to identify stress hotspots that standard platen designs could not detect. Following this, we conducted actual load testing, fabricating a prototype platen and running it at maximum load on an electric injection molding machine for 1000 hours to simulate five years of production. This validated the results of the finite element analysis and revealed potential weak points.

Then, we perform mold compatibility analysis, analyzing how molds of different sizes and weights cause uneven stress distribution on the pressure plate. For example, eccentric mounting of large molds can lead to uneven stress distribution; our finite element analysis takes this into account, thus reinforcing critical areas.

High-rigidity plate design strength optimization

Stress analysis reveals where engineers should reinforce the structure, but optimizing the design strength ensures the plate remains rigid enough without becoming too heavy or reducing motor performance. Topstar’s high-rigidity pressure plate employs three key design features:

Strengthened Rib Structure: We use internal ribs to reinforce stress concentration areas. These ribs are arranged in a grid pattern, matching the motor’s force path, increasing rigidity by 40% without adding extra weight.

Precise Thickening: Instead of overall thickening, we only thicken high-stress areas such as mold mounting holes and actuator connection points. This maintains the lightweight design of the pressure plate while increasing its strength.

Reinforced Mounting Points: Mold clamping holes and actuator mounts are areas of highest stress. We added steel inserts and rounded edges at these points, reducing stress concentration by 65% compared to standard platens.

For electric injection molding machines, achieving a balance between rigidity and weight is crucial. A packaging mold manufacturer who has worked with us stated, “Our previous platens were very heavy, causing our injection molding machine cycle time to increase by 0.5 seconds. Topstar’s high-rigidity platens are lighter yet more rigid, resulting in shorter cycle times, and we haven’t experienced any warping issues.”

Materials and Manufacturing of Durable High-Rigidity Platens

Topstar uses S45C carbon steel for the high-rigidity platens because it combines strength, rigidity, and machinability. Compared to standard low-carbon steel, this alloy offers better resistance to thermal fatigue and microcracks.

Engineers precision-machine the entire pressure platen using a five-axis CNC milling machine, ensuring that the flatness error of the entire surface stays within 0.02 mm. Even minute unevenness can lead to uneven clamping pressure, which is crucial for the precision of electric injection molding machines. After machining the clamping plate, engineers perform heat treatment to eliminate internal stresses generated during manufacturing, preventing the plate from warping once it is put into use. These measures ensure that the clamping plate maintains its rigidity and flatness even after more than 10 years of high-intensity use.

Solving Clamping Plate Damage with High-Rigidity Clamping Plates

Topstar’s high-rigidity clamping plates, based on comprehensive stress analysis, optimized design strength, superior materials, and precision manufacturing processes, completely eliminate cracks, warping, and misalignment. It protects your investment, reduces downtime and scrap, and ensures your electric injection molding machine performs at the speed, precision, and efficiency you expected when you purchased it. As an injection molding machine manufacturer, we are committed to providing solutions to the practical problems faced by injection molding users, enabling you to achieve more efficient production.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/11/10

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/11/10

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/11/10

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/11/10

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar