How to solve the problem of slow response of servo injection molding machine?

2025/07/23 By Topstar

Up to 30% of the cycle delay in servo injection molding machine is attributed to control and drive lags, resulting in a slow response speed and a direct impact on production and product quality. Topstar uses a self-developed unified control system that integrates injection units, clamping units, auxiliary machines, and automation peripherals through a single HMI interface. This unified architecture ensures that all components communicate on a deterministic real-time bus, reducing command delays by up to 50%. This integrated control enables instantaneous adjustments to speed, pressure, and position for the entire injection molding machine. Combined with automatic mold opening position compensation, the injection molding robot can grasp parts with milliseconds of consistent response speed. Let every link bring swift response and high-precision injection molding.

Integrating unified control on servo injection molding machine

A common bottleneck in servo injection molding machines is the disconnection of the control loops between the injection, clamping, and auxiliary systems. For example, traditional systems require separate control commands to start the injection screw, clamping cylinder, and robot removal device, resulting in cumulative delays. Operators must frequently copy parameter changes between modules manually, which slows system response. Therefore, we replaced this multi-node control with a unified self-developed control language, thereby achieving synchronous command transmission. At the same time, all system parameters are displayed on the HMI to facilitate unified adjustments, thereby allowing for immediate recalibration of the entire plastic injection molding machine configuration. The upgrades reduced the injection molding machine’s response time to cycle start commands from 120ms to under 40ms, boosting part repeatability and cutting cycle times by 5%.

Automatic compensation for mold opening of the servo injection molding machine

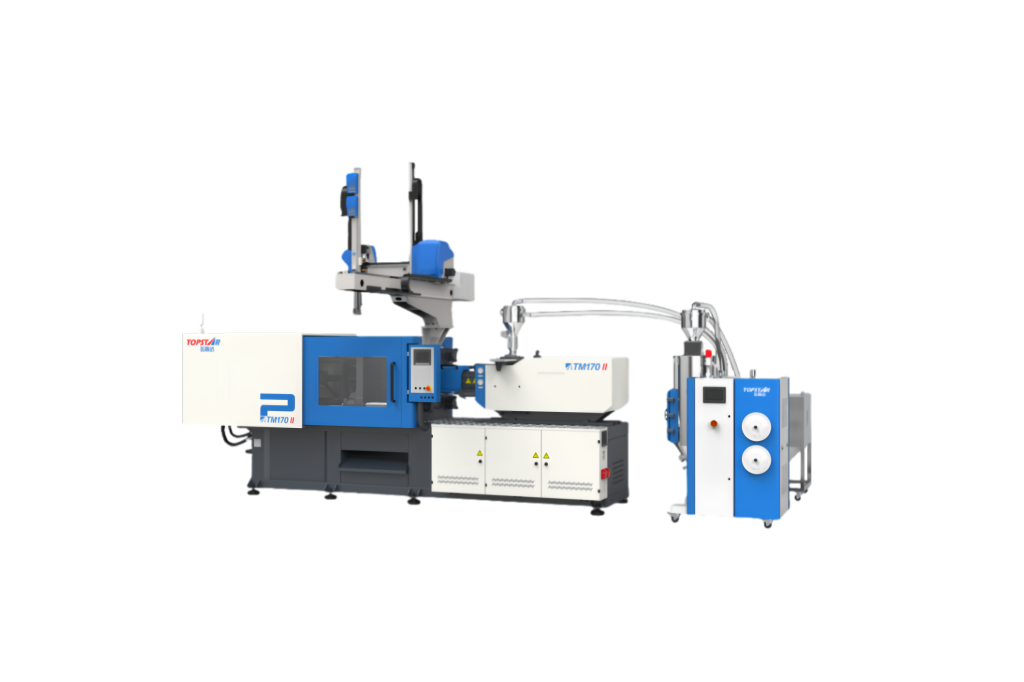

Another key to addressing the slow response of servo injection molding machines is to compensate for the mold opening position automatically. In addition to the standard mold opening time, we also monitor the template position with an error of no more than ±0.01 mm and dynamically adjust the injection molding robot approach trajectory. The injection molding robot starts part removal as soon as the mold safely releases the parts. I installed a position feedback loop on the moving template, using a high-resolution linear scale, and connected it to the real-time controller of the servo drive.

Combined with the motion controller of the injection molding robot under a unified control system, synchronous drive is achieved, which increases the grasping time from a lag of 150 milliseconds to less than 50 milliseconds. In addition, a predictive algorithm based on cycle history enables the system to pre-adjust for thermal expansion and wear, ensuring consistent cycle response even under varying production temperatures and mechanical loads, significantly improving response speed.

Paired with tilted double-shot cylinders and linear guides

Mechanical response also determines the speed of overall injection molding. Topstar’s servo injection molding machines feature tilted double-shot cylinders for mold clamping and ejection, mounted on precision linear guides. The tilted mounting reduces the hydraulic path length by 30%, thereby reducing the travel time of the slide valve. Active voice: I used precision linear guides for the injection unit to reduce mechanical clearance to less than 2 microns. Additionally, the use of double-acting cylinders enables simultaneous opening and ejection movements, further reducing mechanical sequencing delays. The tilted cylinder orientation, combined with high-precision guides, reduces mechanical inertia and friction, allowing for faster mold clamping, opening, and screw reversal speeds. As a result, the injection molding machine can complete the transition between the injection and ejection stages in 80 milliseconds while maintaining the alignment tolerance of precision-tolerance components.

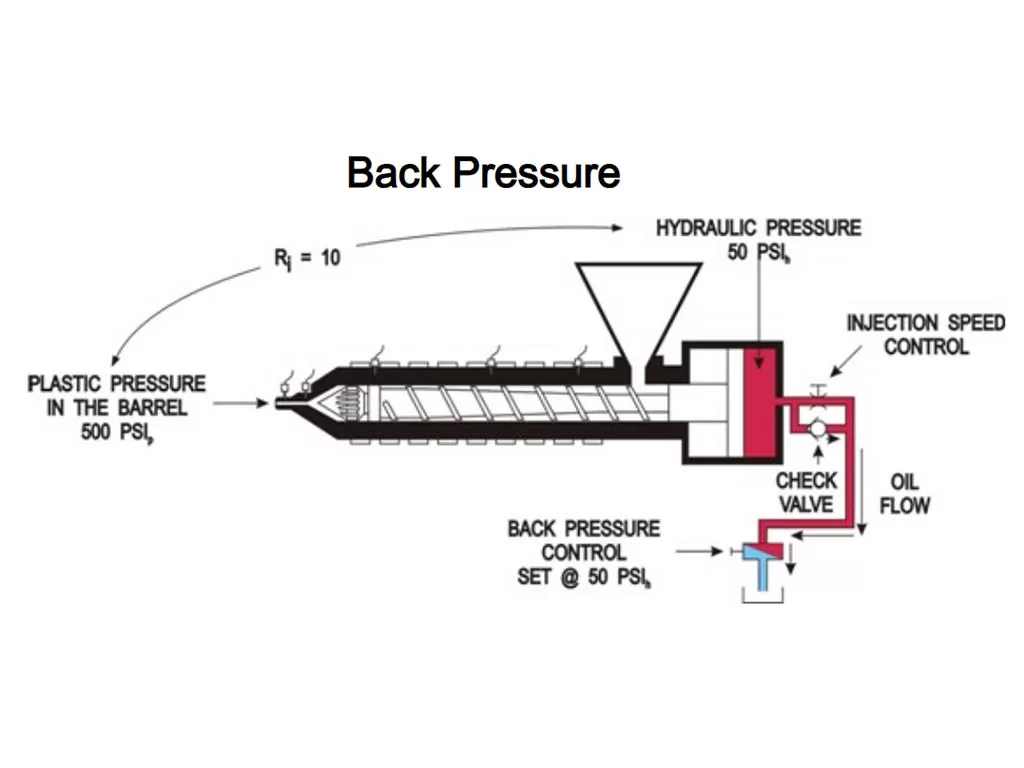

Proportional back-pressure control on servo injection molding machines

The fast response to start injection commands also depends on the accuracy of pressure control. High-response servo valves dynamically adjust screw back pressure during plasticization to maintain consistent melt density and reduce hydraulic overshoot. Our system integrates a 2ms proportional valve directly controlled by the servo drive. This configuration stabilizes the injection pressure within 1 bar of the set value, eliminating pressure fluctuations and ensuring that the forward movement of the screw starts on time. Additionally, the adaptive back pressure curve automatically adjusts to accommodate different injection volumes, thereby improving melt uniformity. Accurate and stable injection curves accelerate cycle conversion and enhance part quality by minimizing fluctuations, flash, and compression deviations in the final molded parts.

Bringing a fast response

Solving the problem of slow response of servo injection molding machines requires a holistic approach, using a unified control architecture, unified HMI adjustments, mold opening compensation related to robot coordination, inclined cylinder and linear guide upgrades, and proportional back pressure control, which can reduce cycle start delays by 30% to 60%, improve part quality consistency, and increase the output of injection molding machine production lines.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/07/23

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/07/23

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/07/23

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/07/23

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar