How to successfully produce soft PU phone cases on a mobile cover making machine?

2025/10/20 By le zhan

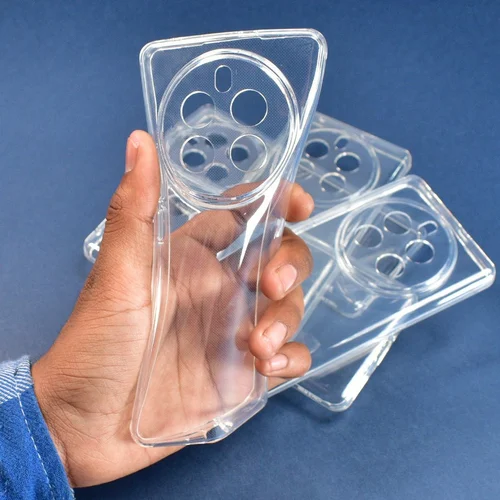

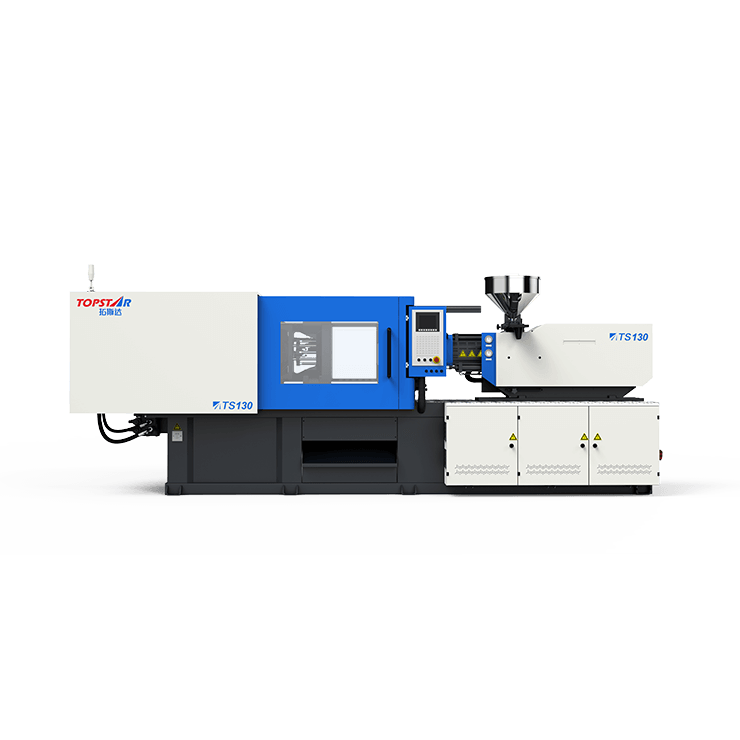

According to a survey by the Mobile Phone Accessories Market Report, 65% of US consumers prefer soft PU phone cases due to their superior feel, anti-slip properties, and shock absorption, making them one of the best-selling phone case types. However, many cases suffer from uneven softness, surface bubbles, or incomplete mold filling. One Indian customer we worked with wasted 15% of their PU material on defective phone cases because their standard mobile cover making machine couldn’t handle PU’s unique viscosity. After collaborating with Topstar, we provided a mobile cover making machine specifically designed for soft PU production—the TS 130 injection molding machine. This injection molding machine perfectly meets all the requirements for PU phone case production.

Why do soft PU phone cases require a dedicated mobile cover making machine?

Soft PU phone cases cannot be produced on just any mobile cover making machines. Soft PU has unique material properties, requiring precise control:

Viscosity: PU is thicker than rigid plastics like PC or TPU, requiring higher injection speeds and pressures to fill mold details and avoid voids ideally.

Temperature Sensitivity: PU degrades above 220°C and exhibits poor fluidity below 180°C. Even a ±5°C temperature difference can destroy its softness or cause surface defects.

Cooling Requirements: Soft PU requires gradual cooling to maintain its flexibility; rapid cooling can make the phone case hard and brittle.

Furthermore, conventional mobile cover making machines often fall short in this regard: their maximum injection speed is limited to 100 mm/s, and they utilize basic heating elements. The Topstar TS 130 injection molding machine, designed specifically for soft and semi-soft materials, easily addresses these challenges.

Speed and Pressure of the Topstar TS 130 Injection Molding Machine

High injection speeds and high pressure are essential for producing soft PU phone cases, and these mobile cover making machines excel in both areas. Here’s how its specifications translate into higher-quality PU phone cases:

Maximum Injection Speed: 145 mm/s: 45% faster than standard machines, ensuring the viscous PU flows quickly into every mold crevice. For phone cases with narrow camera rings, this speed prevents incomplete filling that could result in an unmolded ring.

Maximum Injection Pressure: 290 MPa: High-pressure, densely packs the PU into the mold, eliminating air bubbles and ensuring consistent density.

High-Quality Screw Assembly: The TS 130 utilizes a 32 mm diameter chrome-plated screw with a special thread design that evenly melts the PU and smoothly pushes it into the mold. Unlike standard screws, this design prevents material degradation.

Ceramic Heating Elements for Precise Temperature Control of the PU

Temperature control is critical for soft PU materials. The inlet of this phone case making machine uses ceramic heating elements to ensure the polyurethane (PU) temperature remains within the ideal range, achieving an accuracy of ±1°C. Ceramic elements heat up faster than standard steel elements, providing more precise temperature control. This means the PU temperature can be maintained between 180°C and 220°C, preserving its softness and fluidity.

The ceramic elements also offer fast adjustment sensitivity. If the inlet temperature drops by 2°C, they respond within 0.5 seconds, preventing PU cold blocks and mold filling issues. Maintenance costs are also lower, as the ceramic elements resist corrosion from PU additives and have a service life twice that of steel elements. This reduces maintenance downtime and ensures smooth production. Comparative testing with other equipment demonstrated that the TS 130 consistently maintained an inlet temperature of 200°C throughout an 8-hour PU production cycle.

Step-by-Step Guide to Producing Soft PU Phone Cases on a Mobile cover making machine

Here’s a practical, step-by-step guide on how to produce soft PU phone cases on a mobile cover making machine:

Step 1: Prepare the PU Material

Dry the PU pellets at 80°C for 4 hours. Load the dried PU pellets into the hopper of the making machine, using a material filter to remove any dust or debris.

Step 2: Install the Mold

Install the single-cavity mold on the machine’s platen, ensuring it is evenly aligned. Also, check the mold’s cooling channels to ensure they are clean and connected to the machine’s cooling system.

Step 3: Program Production Parameters

Set the injection speed to 120-145 mm/s, the injection pressure to 250-290 MPa, the feed port temperature to 190°C-210°C, and the cooling time to 15-20 seconds.

Step 4: Run a Test Batch and Make Adjustments

Produce 10-20 phone cases and inspect for defects. If air bubbles are present, increase the injection pressure by 10 MPa. If the case is too stiff, reduce the cooling water temperature by 5°C.

Step 5: Start Full Production

Once the phone cases pass quality inspection, full production can begin. Monitor the consistency of the first 100 cases and check hourly to ensure parameters remain on track.

PU Phone Case Case Study

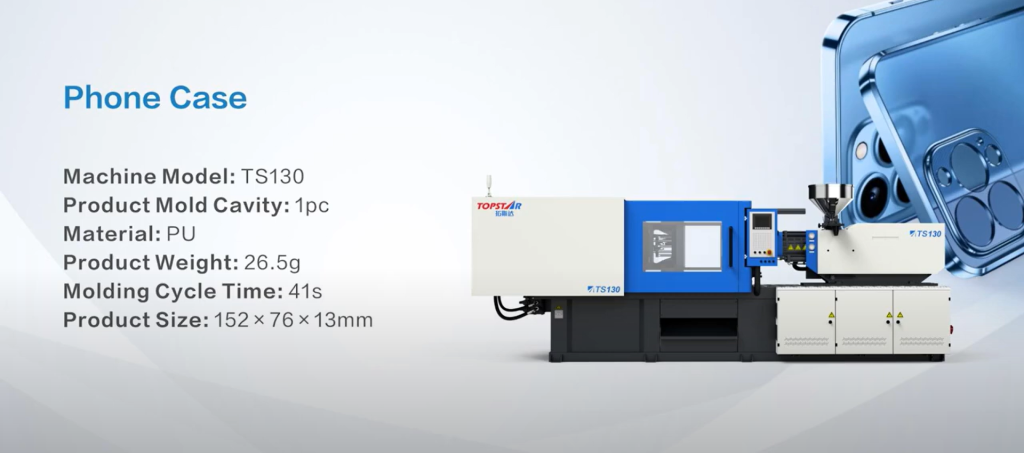

To help phone case manufacturers better understand the actual operation of the TS 130 mobile cover making machine, we’re sharing a real-world project. The goal was to produce soft PU phone cases with precise dimensions and consistent softness. Project details and results are as follows:

Machine: Topstar TS 130 injection molding machine.

Mold: Single-cavity mold.

Material: Soft PU.

Product Specifications: Weight = 26.5 g, Dimensions = 152 mm × 76 mm × 13 mm.

Production Parameters: Injection Speed: 130 mm/s, Injection Pressure: 270 MPa, Inlet Temperature: 200°C, Cooling Time: 18 seconds.

Cycle Time: 41 seconds.

Results: 98.5% yield rate, consistent softness across all products, and dimensional accuracy within ±0.1 mm.

The brand’s production manager noted, “We used to spend two hours a day sorting out defective PU phone cases. With the TS 130, that time has been reduced to 15 minutes, allowing us to produce more cases while reducing waste.”

The TS 130’s Definitive Advantages in PU Phone Case Production

For manufacturers looking to capitalize on the market demand for soft PU phone cases, Topstar’s TS 130 injection molding machine, with its 145 mm/s injection speed, 290 MPa pressure, and ceramic heating elements, addresses the biggest challenges in PU production. This allows you to produce soft PU phone cases that meet consumer expectations for grip, softness, and durability.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/10/20

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/10/20

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/10/20

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/10/20

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- cabinet dryer

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- injection moulding dryer

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar