Injection Molding Trends in 2025: AI and Smart Production Workflows

2025/08/22 By le zhan

In 2025, injection molding will be an intelligent, data-driven manufacturing technology that combines sensors, algorithms, and proven electric drives to achieve scalable, repeatable quality. Topstar’s independently developed all electric injection molding machine controller has moved from the lab to customer production lines. Through deep process optimization driven by proprietary algorithms, we have observed significant improvements in molding consistency and production efficiency in pilot plants. In practice, the controller, combined with precision servo systems and closed-loop sensing technology, has reduced cycle-to-cycle variability and improved the molding yield of quick-connect automotive connectors used in AI servers and for partners such as Xiaomi’s automotive supply chain.

Topstar has also opened a new facility and is committed to providing comprehensive, innovative factory solutions to global manufacturers. In 2025 and beyond, our goal is to embed AI, advanced controllers, and control servo systems into production, transforming scientific advances into operational advantages on the factory floor.

Injection Molding and AI: Process Optimization and Closed-Loop Control

AI has moved from pilot projects to core process control in injection molding. Modern AI no longer serves as a separate analytical layer; it is directly integrated with injection molding machines and controllers to achieve closed-loop optimization. In practice, this means leveraging high-frequency sensor data to train models to predict defects, recommend parameter adjustments, or autonomously adjust setpoints mid-cycle.

This makes the production line adaptive. For example, when the cavity pressure profile drifts due to material batch variations or ambient temperature fluctuations, the AI controller can adjust the injection speed or hold time within the same cycle window to prevent undershot or flashing. In addition to immediate quality improvements, AI capabilities also support predictive analytics. By analysing long-term trends, the system can identify servo current, heater resistance, or cycle anomalies before they lead to downtime. For businesses, this means higher production output while maintaining consistent quality and lowering operating costs.

Electric Servo Drives and Precision Motion Control

Electric injection molding machines have become the benchmark for precision and energy efficiency. In injection molding, they offer finer motion control, faster response times, and more repeatable injection processes than hydraulic systems. Topstar’s fully electric solution combines servo motors, high-resolution encoders, and a proprietary control system to manage screw/platen motion, dosing, and multi-axis mold movements with deterministic timing.

Servo drive control’s dynamic control features, such as active vibration suppression and motion trajectory jerk limiting, reduce mechanical stress on the mold and ejector. This enables all-electric injection moulding machines to achieve shot-to-shot consistency in micro-features, such as contact cavities and thin ribs, in connector moulding, whether for AI server companies or automotive quick connectors.

Precision Solutions for AI Server Companies and the Automotive Supply Chain

AI servers require high-density, heat-resistant connectors that can be assembled reliably at high speeds. Automotive platforms demand connectors that withstand vibration, thermal cycling, and contamination. Our electric injection molding machines, coupled with AI-enhanced controllers, meet the requirements of both sectors by achieving tight tolerance control and repeatable micro-feature molding.

All electric injection molding machines offer cavity pressure balancing control for multi-cavity molds, precise control of holding pressure variations to control flash in thin-walled sections, and micro-injection control to replicate thin ribs without sink marks. For AI server companies, signal integrity depends on precise dielectric positioning; these control measures maintain the impedance profile during the overmolding process. In the automotive sector, we support Xiaomi’s automotive supply chain with precision injection molding solutions for high-reliability quick-connect connectors.

Intelligent Injection Molding Production Workflow

From traditional manufacturing to today’s intelligent manufacturing, the injection molding production workflow integrates machines, molds, material logistics, and quality inspection into a unified system. With the digital twin playing a central role, simulations of the injection molding machine, mold, and process parameters can be run in parallel, allowing changes to be validated before they reach the actual production line.

In the actual workflow, a synchronized data pipeline provides the digital twin with real-time telemetry data: melt temperature history, cavity pressure characteristics, in-mold sensor arrays, and machine kinematics. The digital twin then tests “what-if” scenarios, such as switching resins, adjusting the holding pressure profile, or changing the cycle time, to predict outcomes and recommend the least disruptive optimized path. This allows for rapid recipe changes and minimizes downtime.

Providing intelligent, integrated solutions for the global manufacturing industry

In July 2025, Topstar’s global R&D headquarters officially opened and commenced operations, integrating manufacturing, international sales, and support services to serve its global customers better. Our R&D centre features an intelligent laboratory designed to evaluate artificial intelligence algorithms, sensor fusion methods, and human-machine interaction approaches, thereby making controllers more intuitive and autonomous. The Environmental Reliability Laboratory simulates thermal cycling, humidity exposure, and chemical resistance. The EMC Laboratory verifies that machines and control systems do not damage sensitive electronic components during the injection molding process and comply with regulatory limits. We focus on embodied intelligence, researching key technologies such as intelligent perception, decision-making algorithms, and human-machine interaction. Leveraging AI, controllers, and control servos, we enable our technological achievements to be operational in the production lines of diverse customers worldwide.

Integrating AI and Smart Manufacturing into Injection Molding

By 2025 and beyond, the injection molding process will transform from a process-centric approach to an integrated, AI-enabled manufacturing technology. Electric injection molding machines, tightly integrated with intelligent controllers and high-bandwidth servos, deliver the precision required for advanced connectors, electronics, and automotive parts. Intelligent workflows and laboratory-supported validation shorten time to market and reduce the risk of scale-up failure. Topstar is also accelerating its global expansion, leveraging its core technologies to bring more innovative achievements to the world and contribute to the global upgrade of smart manufacturing.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/08/22

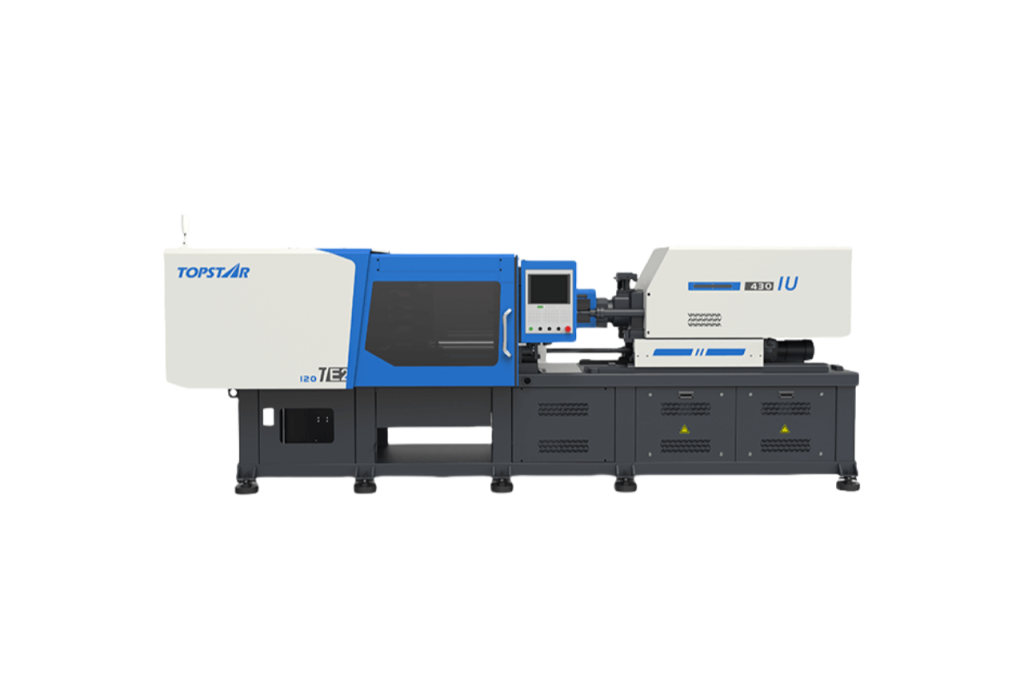

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/08/22

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/08/22

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/08/22

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- cabinet dryer

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- injection moulding dryer

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar