Is it possible to achieve ultra-long stroke mold opening on a plastic injection molding machine?

2026/01/06 By le zhan

When you need to injection mold a large, multi-part automotive housing, or a deep, multi-cavity cosmetic container, the two halves of the mold need to move an exceptionally long distance to clear complex cores, inserts, or multi-stage ejection systems. On traditional plastic injection molding machines, you either accept limited mold geometries or purchase larger, slower machines, sacrificing production cycle time. What if a plastic injection molding machine could simultaneously achieve ultra-long mold opening strokes, millimeter-level positioning accuracy, and fast, stable platen movement without compromising production speed or reliability? This combination is entirely possible with Topstar’s Ts series toggle plastic injection molding machine.

Why are ultra-long strokes important for plastic injection molding machine?

Ultra-long mold opening strokes are crucial in a variety of applications, including deep-drawn containers, inserts with high ejector pins and overmolding, multi-stage ejection, long-stroke core pulling, and molds requiring large interlocking or multi-layer demolding. Plastic injection molding machines that support long-stroke mold opening allow engineers to design parts with complex undercuts, telescopic cores, or multi-layer structures without time-consuming secondary processing.

Specific benefits include:

Single-shot production: Reducing assembly, secondary processing, or manual post-processing by providing the necessary geometry in the mold in a single cycle.

Higher automation: Long strokes allow for safe integration of injection molding robots, insert pick-and-place devices, or in-mold labeling equipment that requires extra clearance.

Faster product changeovers: Mold maintenance and changeovers become easier and less time-consuming due to longer mold opening times and precise platen control.

However, achieving long strokes without compromising platen parallelism and stability is a major engineering challenge. Long strokes amplify deflection, place higher demands on the guiding system, and increase the mechanical work that the drive system must perform. Therefore, Topstar has developed a new diagonal toggle mechanism layout, combined with modern control and guidance technologies, to enable ultra-long mold opening and achieve stable, precise mold opening.

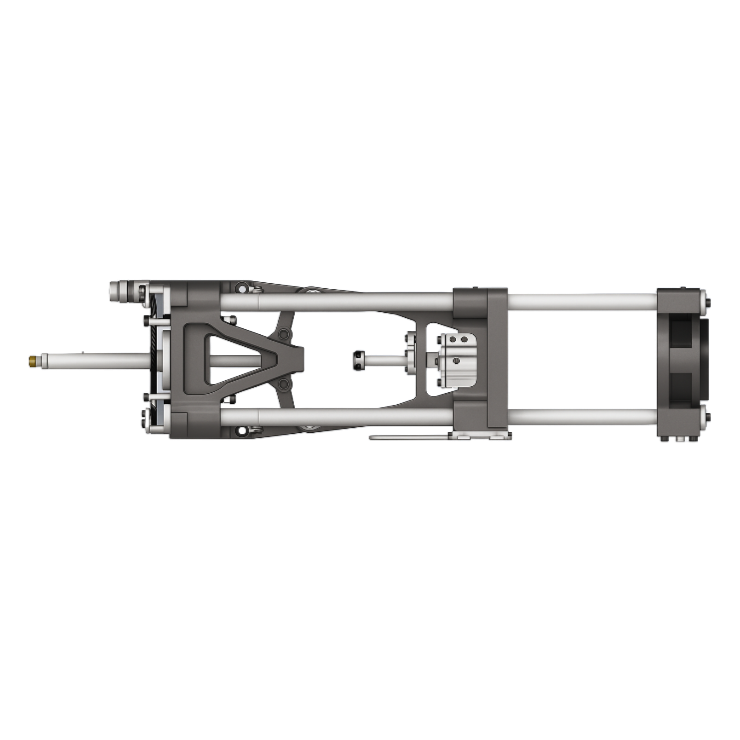

Achieving Ultra-Long Stroke Mold Opening with a Diagonal Hinge Layout

Toggle mechanisms are a traditional solution that uses mechanical advantage to convert small actuator movements into large platen opening and closing strokes. However, the classic linear toggle mechanism layout is typically limited by its geometry: long strokes require longer toggle links and larger platen spacing, which increases inertia and reduces stiffness. Topstar’s innovation lies in adopting a diagonal toggle mechanism layout, readjusting the link geometry to achieve ultra-long strokes while improving stiffness and providing smoother kinematic characteristics.

The main advantage of the diagonal hinge layout is higher mechanical advantage within the effective range of motion, allowing for larger opening distances without the need for oversized actuators. This diagonal geometry enables medium-sized cylinders or servo actuators to drive longer platen strokes than equivalent-sized straight-link mechanisms. Simultaneously, the machine bed and frame distribute the link loads into more rigid load paths, reducing the deflection of the toggle links.

This enables ultra-long-stroke mold opening with large platen travel and robust structural support, reducing deformation and helping maintain mold opening accuracy to less than 1 mm.

Achieving less than 1 mm mold positioning accuracy on plastic injection molding machine

Achieving mold opening positioning accuracy of less than 1 mm at ultra-long strokes depends on controlling three mechanical factors: platen stiffness, guiding accuracy, and balanced load distribution. Ultra-long-stroke injection molding machines must be carefully designed in every aspect.

- Platen Design and Reinforcement

The platen must resist bending throughout its entire stroke. Topstar uses thickened platen sections with internal reinforcing ribs and an optimized box-beam geometry to increase moment of inertia without adding excessive mass. This enhances the platen’s resistance to bending during long-stroke opening.

- High-Precision Guiding System

As the stroke increases, the importance of guide rail design becomes increasingly critical. Topstar uses preloaded linear guides or high-preload crossed-roller bearing structures to minimize clearance. Where applicable, multi-rail structures can distribute the load and prevent tilting.

- Toggle and Drive Stiffness

The link bearings and pivots of the diagonal support rods utilize high-grade spherical roller bearings and hardened pins. Low-clearance link joints reduce micro-movements that would otherwise accumulate over stroke and time. Servo or hydraulic actuators are installed using rigid couplings and anti-backlash devices. The actuator support structure transmits force directly to the machine base, preventing bending of the platen assembly.

Mold Design and Considerations

Achieving ultra-long strokes in a plastic injection molding machine is only part of the solution; the mold design must fully utilize the stroke advantage while avoiding damage and maintaining production cycles. Integration and commissioning are crucial.

Mold Design:

Balanced Load Distribution: Install and support heavy core components or long lifters to distribute the load near the platen’s center, reducing the tilting force arm that can occur during long strokes.

Lifters and Core Mechanisms: Long core lifters must have anti-buckling support, guide rails, and segmented movement to avoid sudden load changes that could affect platen parallelism.

Ejection and Demolding Sequence: Employ a multi-stage ejection sequence coordinated with the platen movement to avoid sudden shifts in the center of gravity. Phased movement reduces transient loads and enables faster, smoother long-stroke cycles.

Mold Cooling and Thermal Stability: Ensure that thermal gradients do not cause differential expansion, thus reducing mold opening accuracy during long production runs.

Practical, Precise Ultra-Long Stroke Mold Opening

By systematically optimizing the injection molding machine’s mechanism geometry, structural rigidity, guiding accuracy, and drive control, Topstar TS series injection molding machines have successfully overcome the traditional technical bottleneck: “the longer the stroke, the lower the accuracy and the slower the speed.” Using a diagonal hinge layout, it achieves ultra-long mold opening distances while maintaining high rigidity, high stability, and millimeter-level positioning accuracy, enabling complex core mechanisms, multi-stage demolding, and high-automation integration to be completed stably within a single molding cycle.

Frequently Asked Questions

1. What constitutes an “ultra-long” mold opening stroke on an injection molding machine?

While there is no single numerical standard, “ultra-long” typically refers to a platen stroke significantly exceeding the standard mold clearance. This is usually several hundred millimeters – necessary for deep ejection, high inserts, or multi-layer ejection. The specific definition depends on the mold sizes commonly used in your factory.

2. How does Topstar ensure mold opening position accuracy of less than 1 mm at such long strokes?

Topstar’s approach is multi-layered: a diagonal toggle mechanism reduces link deflection; reinforced molds and multiple guide rails minimize bending; and model-based closed-loop control applies feedforward and real-time compensation to correct predictable elastic deflection.

3. Will the extra-long stroke increase my cycle time?

Not necessarily. Through optimized toggle geometry and coordinated motion control, long strokes can be achieved with minimal increase in cycle time. In many Topstar systems, optimized acceleration/deceleration profiles and integrated motion blending features enable fast opening and closing without increasing cycle time.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2026/01/06

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2026/01/06

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2026/01/06

- What factors can cause delays in the injection molding process of plastic molding machine? 2026/01/06

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar