Low speed 20~28 rpm: Topstar soundproof granulator achieves energy-saving and low-noise processing

2026/01/23 By le zhan

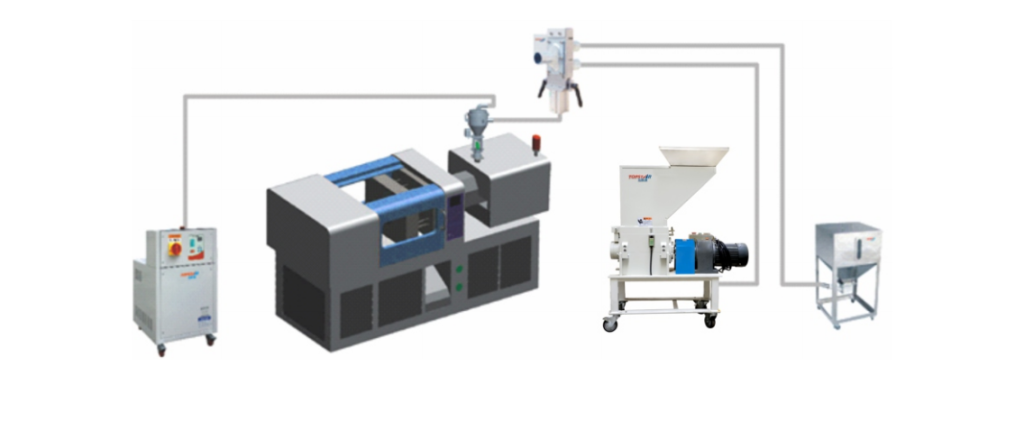

Noise, dust, and energy waste are not just disruptions in the production process; they represent real costs. When high-speed granulators hum in plastic recycling or production workshops, businesses incur high electricity bills, worker fatigue, and additional cleanup. Topstar’s soundproof granulator, designed with a low-speed (20-28 rpm) cutting approach, effectively addresses this issue. Topstar combines low-speed gear-driven cutting, a hollow-shaft gear motor, and precise acoustic design to effectively reduce noise, conserve energy, and deliver cleaner, higher-quality recycled materials for subsequent processing.

Low Speed 20-28 rpm: Advantages of Soundproof Granulator for Cutting Plastic

The function of a soundproof granulator is simple: more precise cutting, not faster. At 20–28 rpm, the rotor (cutter) applies higher torque for a more extended engagement time, altering the material’s behavior during particle size reduction.

Firstly, the low-speed cutting reduces heat generation. High rotational speeds increase friction and shear heat at the cutting interface, softening the polymer, promoting melting, and generating fine powder and dust. For rigid, brittle plastics (such as PC, nylon, and ABS), lower speeds of 20–28 rpm keep the material below its critical softening point during cutting. This results in reduced thermal degradation, improved melt-flow properties during downstream processing, and fewer impurities in the particles.

Secondly, the cut quality is improved. Low-speed, high-torque operation, combined with a gear-driven cutter design and a thicker cutter geometry, produces particles with a more uniform size distribution. This uniformity improves material feeding and metering into the hopper, dryer, and extruder, reducing screen clogging and machine downtime.

Thirdly, noise generation decreases significantly as rotor speed decreases. Aerodynamic and impact noise are proportional to rotational speed and cutting frequency; operating at 20–28 rpm reduces both. In practice, operators will find lower production line noise, less employee fatigue, and a reduced need for large-scale acoustic retrofits.

Hollow Shaft Gear Motor Drive: Compact, Maintenance-Free, and Space-Saving

A key feature of Topstar’s design is its hollow-shaft gear-motor drive. This structure integrates the motor and reduction gears into a single compact component, directly driving the rotor shaft without the separate gearbox and couplings commonly found in traditional pelletizers.

The hollow-shaft gear motor uses sealed, grease-filled bearings and gear sets, designed for lifetime lubrication. This eliminates the need for routine gearbox lubrication and reduces the risk of lubricant contamination, a significant advantage for processing food contact materials or high-purity polymers.

Furthermore, integrating the reduction gears within the motor housing and achieving direct drive via the hollow shaft reduces the overall footprint. For plants requiring a compact unit layout or wishing to install the soundproof granulator near injection molding machines or recycling hoppers, the smaller size simplifies logistics. Simultaneously, the hollow-shaft gear motor provides the high torque required for low-speed, high-resistance cutting while maintaining stable thermal performance. Topstar’s motor selection balances torque output and duty cycle to prevent overheating during continuous operation. These advantages include quieter operation, less vibration transmitted to the frame, and easier direct integration with soundproof enclosures.

Energy Saving and Operating Efficiency

Energy efficiency is more than just an electricity bill. It also determines equipment size, cooling requirements, and long-term operating costs. This soundproof granulator achieves energy savings through several complementary mechanisms.

Higher rotor speeds generate greater air resistance in the cutting chamber and increase friction on the pellet surface, thereby increasing power demand. In contrast, low-speed, high-torque cutting concentrates energy on the mechanical shearing of the material, rather than wasting energy on airflow and heat. The result is a more efficient conversion of electrical input into practical cutting work. In many applications, this translates to a significant reduction in kilowatt-hours per kilogram of recycled plastic compared to conventional high-speed granulators.

Furthermore, matching the rotor geometry, blade profile, and fixed-bed blades is crucial. Topstar engineers designed the cutting head for low-speed operation—a thicker blade body, staggered blade rows, and gear-driven synchronization—ensuring efficient shearing and minimizing rework. Because the rotor is equipped with heavier, stronger blades, grinding is reduced, cutting efficiency is increased, and blade life is extended, reducing energy consumption per cut.

Soundproof Granulator Design: Eliminating Noise Pollution in Factory Workshops

The Occupational Safety and Health Administration (OSHA) and local standards stipulate noise exposure limits; excessive factory noise reduces worker comfort and productivity. Topstar’s soundproof granulators address noise issues on multiple levels, achieving a tranquil granulation process.

The sound energy generated by cutting and impact is closely related to rotational speed. At 20–28 rpm, the primary sources of airborne noise—blade impact, aerodynamic whistling, and bearing harmonics—have significantly lower amplitudes and frequencies than at higher speeds. This reduction in base noise results in smoother acoustic characteristics. Topstar equips low-speed rotors with a carefully designed soundproof enclosure. This enclosure is made of thick steel plates, filled with sound-absorbing foam, and equipped with restraint-layer damping to effectively absorb sound and reduce radiated noise. Elastomer vibration isolation is used at the mounting points to prevent structural noise from propagating to the floor or support platform.

Furthermore, the hollow shaft gear motor provides smooth, continuous torque, avoiding sudden speed changes and coupling backlash, both of which generate pulse noise. The gear profile is precisely cut and balanced to minimize gear squeal. In addition to easier compliance with regulatory standards, a quieter granulator reduces the need for hearing protection and improves communication around the equipment.

Achieving Uniform Particles, Minimal Powder, and Long Material Life

The primary function of a plastic granulator is to control particle size and integrity. Topstar’s low-speed plastic granulator offers numerous advantages that translate into superior downstream processing performance.

Low-speed cutting reduces micro-fragmentation and pulverization; thicker blades and gear-driven shearing produce uniform, blocky granules, ensuring a stable feed of material into the dryer and hopper. Uniform granules reduce bridging, improve feeder metering performance, and minimize the generation of fine dust that can lead to flow problems and oxidation.

For complex and brittle materials such as PC, nylon, glass fiber-reinforced composites, and ABS, low-speed, high-torque cutting reduces surface melting and localized heating, thereby preventing stringing or partial melting. This process results in better surface integrity, better filler dispersion, and improved mechanical properties when manufacturers reuse recycled materials in production processes. Furthermore, Topstar offers SKD-11 tool steel or other wear-resistant blade materials suitable for highly abrasive or heavily filled materials. Combined with low-speed grinding, these durable blades extend maintenance intervals and maintain stable particle size control over extended periods of operation.

Achieving Energy-Saving and Low-Noise Processing

Topstar’s soundproof granulators utilize a low-speed rotor (20-28 rpm) and a hollow-shaft, geared-motor drive, providing a balanced solution for modern plastics processing. It reduces noise pollution, lowers energy consumption, simplifies maintenance, and produces cleaner, more uniform pellets suitable for high-quality recycling and reprocessing.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2026/01/23

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2026/01/23

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2026/01/23

- What factors can cause delays in the injection molding process of plastic molding machine? 2026/01/23

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar