Special solution for automotive parts injection molding of PMMA thick-walled headlights

2025/09/01 By le zhan

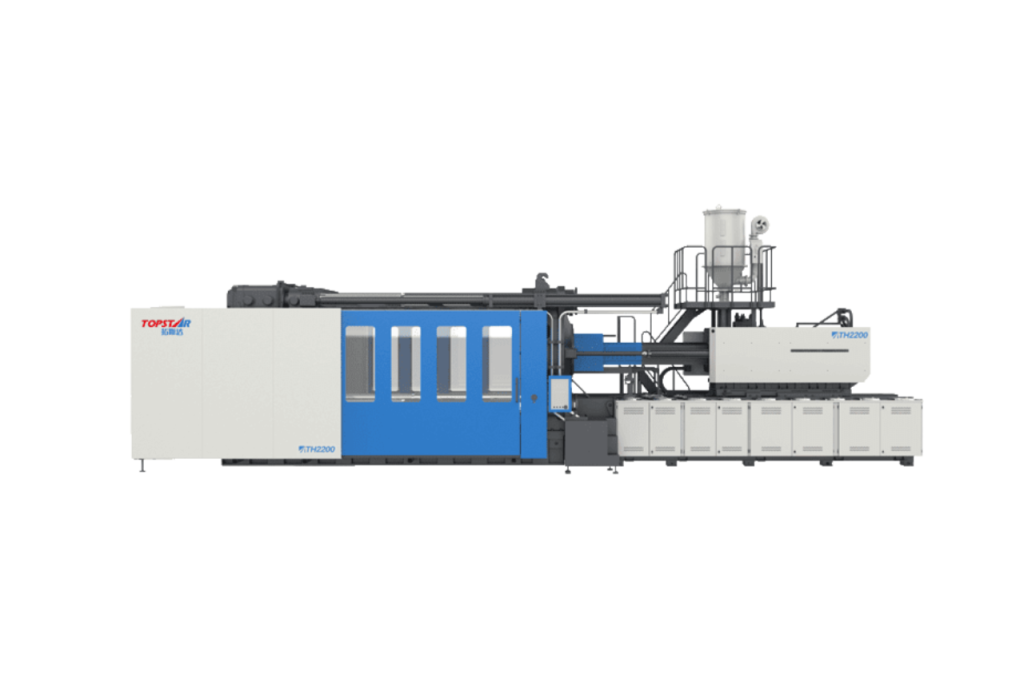

For the automotive parts injection molding of thick-walled PMMA headlights in automotive components, Topstar utilizes a direct injection molding machine equipped with a patented center-clamping mechanism. Specifically, this method enables two-shot moulding of 35 mm thick headlight lenses, significantly improving product quality and optical performance while reducing cycle time. The direct injection molding machine systematically addresses these issues by ensuring uniform clamping force distribution at the center of the mold plate, achieving near-perfect mold parallelism and fit, and providing a controlled injection profile. These features work together to effectively eliminate air entrapment, reduce undershot, and produce a dense, void-free polymer structure within the light-guiding geometry.

Material Properties of Thick-Wall PMMA for Automotive Parts Injection Molding

PMMA offers excellent optical clarity, high light transmittance, and good weather resistance—properties highly valued in headlight optics and decorative lenses. However, PMMA has low thermal conductivity and is sensitive to moisture and shear forces, requiring careful upstream control. Thick-walled PMMA parts, such as 35mm lenses, exacerbate several phenomena. Long filling times lead to air entrapment, temperature gradients that create residual stresses, and slow cooling that can lead to differential shrinkage and sink marks.

Key material considerations include the drying strategy, melt temperature window, and shear history. PMMA is somewhat hygroscopic; even small amounts of moisture can cause microvoids when injected into thick sections. Therefore, the desiccant must be continuously dried to the manufacturer’s specified dew point. Melt temperature must be tightly controlled. Similarly, the screw design must strike a balance between sufficient plasticization and low shear to avoid localized degradation and dark spots caused by burnt polymer. Furthermore, mold temperature control is essential. Uneven cooling can lead to localized shrinkage and internal stresses, which scatter light and reduce optical uniformity.

Core Injection Molding Machines in Automotive parts injection molding

The architecture of the injection molding machine determines the achievable process window for demanding automotive parts injection molding applications. Direct injection moulding machines with patented centre clamping structures offer the mechanical stability and process repeatability necessary for producing thick-walled PMMA headlamps.

The center clamping of a direct injection molding machine evenly distributes clamping force across the entire platen. In large headlight moulds, off-centre clamping can lead to slight tilting, misalignment, and fluctuations in cavity pressure. These can lead to flow line variations, insufficient packing, and air entrapment. Topstar’s patented center clamping technology concentrates and balances force in the center of the mold while supporting the outer areas with a system of guide rods and platens. This ultimately eliminates micro-gaps that can trap air. Another unique advantage of direct injection molding machines is their robust, low-flow hot runner manifold and rigid injection platform, which minimize the melt’s travel distance from the screw to the mold cavity. This reduces pressure loss, maintains injection inertia, and enables more precise speed-pressure conversion.

Targeted Process Control Strategies

Injection molding process control is crucial for translating machine performance into product performance. For automotive parts injection molding, especially thick-walled PMMA parts, the optimal filling and packing strategies differ significantly from those for thin-walled thermoplastic parts. The goal is to fill the cavity while minimizing shear and air entrapment, then apply sufficient holding/compression pressure to eliminate shrinkage and voids during part solidification. High injection pressure, combined with a low, constant injection speed, produces a dense, bubble-free melt front. High pressure ensures that the molten polymer penetrates all thin-walled sections and undercuts, helping to squeeze out trapped air through vents or vacuum ports. Consequently, controlled and constant filling maintains laminar flow and a consistent pressure distribution.

Topstar’s direct injection molding machines, equipped with a forward-travel platform and rigid control system, enable close coordination of the injection, compression, and clamping phases. Furthermore, a tapered, multi-step holding pressure profile reduces residual stresses, followed by a gradual reduction in pressure to prevent overstressing thick-walled sections. An integrated cavity pressure sensor empirically determines the V/P switching point. This sensor feedback enables closed-loop control, ensuring optimal switching even during long-term production runs despite changes in mold or resin parameters.

Precise Pick and Place with backend Automation

In the backend of automotive parts injection molding production, Topstar integrates a six-axis robot into its automated production cell, providing deterministic handling during the injection molding process, which is critical for thick-walled PMMA headlights.

Six-axis robotic handling improves repeatability. After the first shot, semi-finished lenses are very fragile and often thermally unstable. The six-axis robot securely grasps the part, performs a drying or temperature stabilization pause, and places the part into the mold for the second shot with micron-level positioning accuracy. Furthermore, the robot’s motion trajectory can be adjusted to avoid dynamic stress or markings on the part surface. Automation goes beyond pick and place; cameras and machine vision systems can inspect the semi-finished product surface for bubbles, flow marks, or contamination before the second shot. Defective parts can be automatically classified as rework or scrap. In addition, synchronizing robots and presses via deterministic I/O or fieldbus reduces cycle times and ensures accurate handovers at optimal temperature and dimensional conditions.

Injection Molding Solutions for High-Quality Thick-Wall PMMA Headlights

Producing high-quality, thick-wall PMMA headlights for automotive applications requires systematic production planning, including material specifications, dedicated molds, direct injection molding machines, precise process control, optical-grade injection platforms, and automated robotic handling. Topstar’s approach seamlessly integrates these elements. A patented centre clamping mechanism ensures mould parallelism and uniform force distribution. A forward-moving injection platform and dual-exit hydraulic cylinders guarantee shot integrity. A six-axis robot enables precise two-shot workflows with minimal manual intervention. These technologies, combined with stringent drying and melt control, as well as cavity pressure-based closed-loop control, address the most challenging defects in automotive parts injection molding, while reducing cycle times and increasing production output.

Common Problems in Injection Molding Thick-Wall PMMA Headlights

Q1. Why is center clamping crucial for thick-wall PMMA headlights?

A1: Center clamping balances clamping force across the mold, maintains platen parallelism, and minimizes micro-gaps. This uniform contact prevents air entrapment and ensures consistent cavity pressure.

Q2. How does the injection-compression process help reduce optical defects in thick parts?

A2: The injection-compression process fills the cavity in a controlled manner with the mold partially open, then compresses to the final thickness. This reduces shear forces and flow marks, improves surface replication, and enables higher final packing pressures, thereby eliminating voids and sink marks.

Q3. What role do six-axis robots play in the automotive parts injection molding?

A3: Six-axis robots enable precise and repeatable handling of semi-finished parts between injections, ensuring accurate positioning of the second shot.

Q4. What process parameters can prevent yellowing and black specks in PMMA?

A4: Key parameters include melt temperature control, strict resin drying, low shear during plasticization, appropriate screw design, and maintaining a stable injection profile.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/09/01

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/09/01

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/09/01

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/09/01

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- cabinet dryer

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- injection moulding dryer

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar