What is the best phone cover making machine for mass production?

2025/08/08 By Topstar

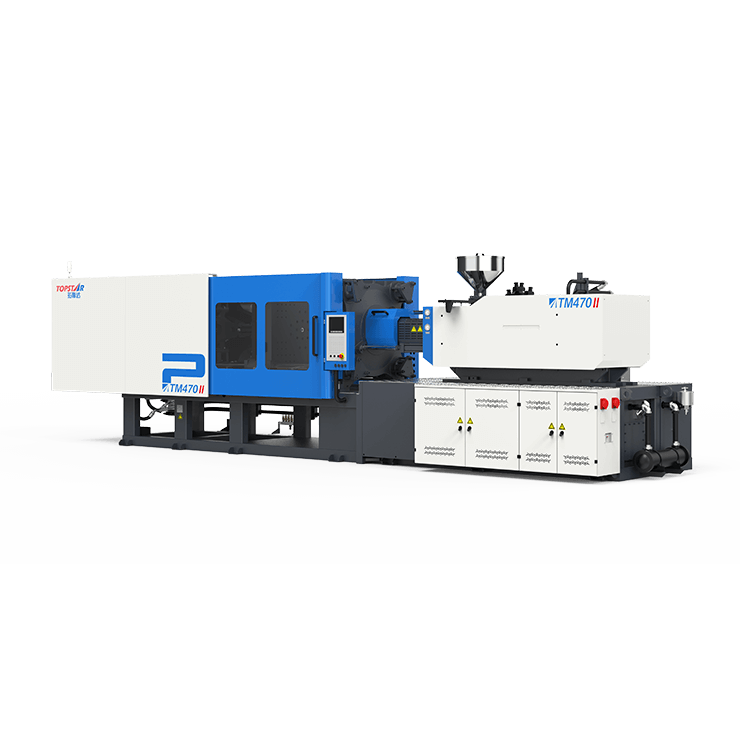

Topstar’s TMII series servo-driven injection molding machines are ideally suited for mass-producing phone cover making machine. In high-volume phone case injection molding, throughput, repeatability, and minimal downtime are more critical than ever. The TMII’s integrated molding concept enables multiple machines to operate under a unified control interface, enabling factory-wide synchronization, simpler operator workflows, and faster line changeovers. Furthermore, its automatic mold opening position compensation and precise robotic gripping reduce mechanical deviations within each cycle, directly increasing yield and reducing scrap. It delivers the consistency and flexibility required for high-volume mobile phone case injection molding.

Core Production Challenges of phone cover making machine

Mobile phone cases typically require ultra-thin walls, precise snap-fits, tight dimensional tolerances, and a flawless appearance. These constraints create several technical pressure points: melt stability, mold temperature control, warpage management, and consistent demolding. Furthermore, color matching and surface texture requirements place stringent demands on material handling and process control.

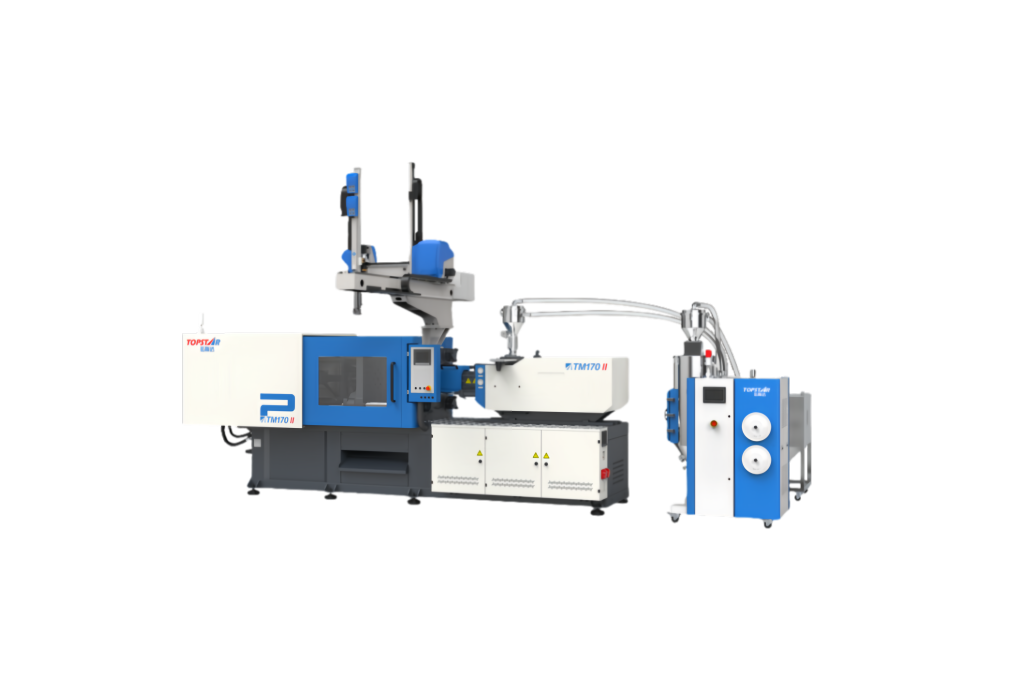

At the same time, large-scale production also requires consideration of molding cycle time, and automation is highly demanding, necessitating the use of injection molding robots for part removal during the molding process. Therefore, phone cover making machines for mass production must combine fast, precise injection control with advanced thermal management and seamless automation integration. When you comprehensively address these aspects, you can achieve the desired balance between speed, repeatability, and product integrity.

Servo-driven injection molding machines are more suitable for a phone cover making machine for mass production

Servo-driven injection molding machines are primarily chosen because, unlike traditional hydraulic systems, they offer precise, repeatable motion control with millisecond response times, enabling highly accurate injection profiles, fast recovery, and reduced cycle-to-cycle variability. For mobile phone case injection molding, this enables tighter control over injection speed, pressure, and holding pressure profiles. Furthermore, servo motors significantly reduce energy consumption during idling and repositioning, lowering operating costs for mass production.

The Topstar TMII series injection molding machines combine these servo advantages with a dedicated injection unit design and low-damping mechanism, ensuring a phone cover making machine that balances speed and precision. Furthermore, servo drive control provides precise closed-loop position and force control, minimizing over-packing, flash, and micro-burn marks. It also supports variable pressure hold and precise back pressure control, helping to complete the injection molding of complex mobile phone cases and reduce defects.

Integrating Injection Molding and Automation to Improve Line Efficiency

For large-scale production, the performance of a single phone cover making machine is necessary, but not sufficient. Your factory needs integrated automation. The “Injection Molding in One” concept of the TMII series injection molding machine allows multiple phone cover making machines to be connected under a single HMI/control framework, streamlining recipe deployment, synchronizing injection molding robot motion, and reducing human error during mold changes. This architecture supports automatic mold opening position compensation, ensuring that the injection molding robot picks up parts at the exact target point during each cycle. Combined with precise gripping strategies, this reduces mispick and downstream rework. Furthermore, the injection molding machine supports standardized communication protocols, enabling real-time feedback with the MES system. This provides visibility into cycle rates, cavity balance, and process deviations across the entire production line.

Phone cover making machine suitable for multi-material processing

Mobile phone cases utilize a variety of polymers, including PC, ABS, PC/ABS, and others. Each material has different melt sensitivities, shear behaviors, and thermal stability. Therefore, mass-production phone cover making machines must provide precise melt management. Topstar’s TMII injection molding machines feature a wear-resistant, coated screw that delivers stable, shot-by-shot melting and homogenization, which is particularly important when producing filled or abrasive compounds. Discharge temperature control, meanwhile, stabilizes the melt temperature at the nozzle and gate, preventing degradation, color streaking, or inconsistent surface quality.

Furthermore, the TMII’s standard configuration supports tight temperature zone control, fast-response thermocouples, and adaptive screw profiles, allowing you to run a broader range of adhesive and coating-compatible formulations without frequent manual adjustments. This translates to shorter cleaning cycles, less waste, and higher first-pass yields.

Quality, Precision, and Post-Molding

Phone cover making machines for mass production must produce parts that meet both aesthetic and mechanical requirements. These precision components require low backlash, rigid platens, and stable clamping force. The TMII’s rigid structural design and integrated servo control achieve these characteristics. Furthermore, the machine’s advanced injection control reduces common visual defects. Combined with optimized mold temperature control and conformal cooling, it achieves a consistent surface finish, minimizing the need for secondary polishing or repair. The TMII also supports rapid, one-click mold replacement, speeding up maintenance and mold changes. Therefore, selecting a TMII injection molding machine for mobile phone case manufacturing can reduce cycle-to-cycle variability, enhance appearance quality, and improve overall quality in high-volume production.

Optimally Suitable for phone cover Injection Molding

The Topstar TMII series is ideally suited for large-scale injection molding of mobile phone cases. Its servo drive precision, integrated line control, automatic mold adjustment, coating screw durability, and discharge temperature control minimize defects, reduce setup time, and maximize uptime. Furthermore, the TMII’s scalability allows you to start with a single unit and expand to a multi-machine cluster under the same monitoring interface, while preserving process parameters and production recipes for greater consistency across large-scale production.

Related article recommendation: https://www.topstarmachine.com/best-phone-case-making-machine-for-large-scale-manufacturing/

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/08/08

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/08/08

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/08/08

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/08/08

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- Auxiliary Equipment

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- gravimetric blender

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic auto loader

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic dryer for injection molding

- plastic forming equipment

- Plastic Granulators

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Screw dosers

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar